The average person might not realize it, but Beryllium copper is used safely every single day and in a multitude of industries.

Your smartphone’s battery and electronic connectors are made with Beryllium copper. The computer you work from uses Beryllium copper with springs, connectors, and switches. And the airplanes that take you to beautiful locations around the world use Beryllium copper alloy in their bearings, wing flaps, and emergency doors.

Beryllium copper has many advantages and is one of the best metals when electrical conductivity is essential. It’s one of the strongest copper alloys that can be formed easily for thin metal parts and complex shapes. It can also be produced with or against the grain, age-hardened, and has great ductility.

E-Fab uses Beryllium copper in a wide range of fields and industries. Its strength, electrical conductivity, thermal conductivity, non-sparking nature, and lack of magnetic properties are the main reasons for this. We’ll discuss the distinctive qualities of Beryllium copper that make it such a popular choice and why it is safe to use.

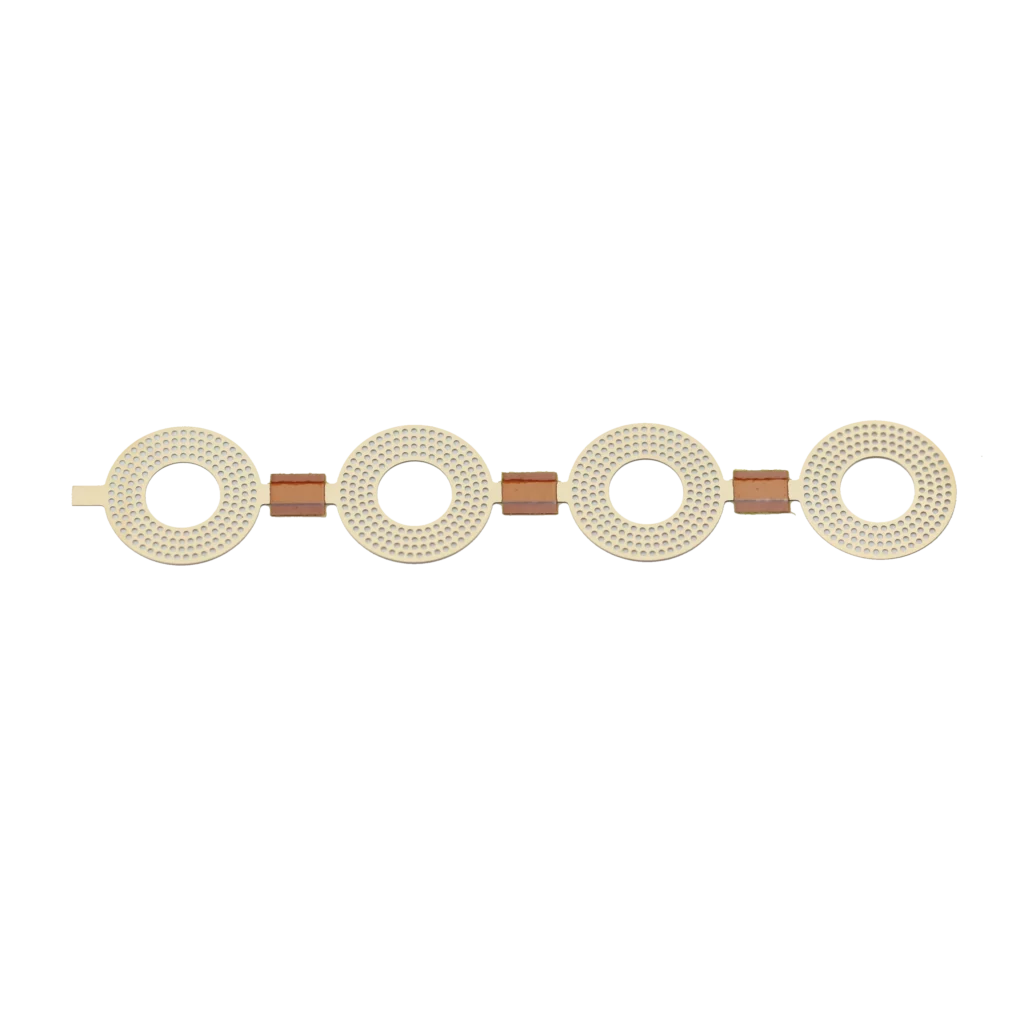

Common Beryllium Copper Products

Electronic connectors, telecommunications equipment, computer components, and miniature springs are among the products that most frequently use Beryllium copper. The exceptional adaptability of Beryllium copper is renowned for:

- High electrical and thermal conductivity and high ductility

- The ability to be stamped into complex shapes with tight tolerances while maintaining its strength

- Good corrosion and oxidation resistance

- Excellent metalworking, forming, and machining qualities

E-Fab knows that Beryllium copper is the metal of choice when it’s vital to maximize electrical properties, memory, and strength with non-magnetic and non-sparking characteristics. We leverage these qualities when manufacturing microstrip contacts, contacts, and springs.

Where Can You Find Beryllium Copper Parts

The most common uses for Beryllium copper are in electronic connectors, telecommunications products, computer components, and small springs. Because of the high electrical and thermal conductivity and high ductility, Beryllium copper is used in everyday items that make our modern lives easier and more convenient. Here are a few items you can find Beryllium copper in:

- Computers: Connectors, relays, circuitry

- Smartphones: Batteries, connectors, charging cables

- Military Applications: Missile gyroscopes, sensors in satellites, mirrors in surveillance equipment

- Medical Uses: Pacemakers, CAT scanners, MRI machines

Why Beryllium Copper is Ideal for Thin Metal Parts

Beryllium copper transmits heat and electricity very well, making it ideal for thin metal parts in electronics and telecommunication parts. It’s naturally corrosion-resistant and non-magnetic, making it ideal for electronic parts such as smartphones that can easily damage magnetic waves and water damage.

Additionally, the non-sparking qualities of Beryllium copper reassure that whatever product you use will not start a fire or damage the equipment. Beryllium copper is an ideal choice if you’re manufacturing thin metal parts like:

- Connectors

- Relays

- Circuit boards

- Springs

- Switches

What’s the Difference Between Beryllium Copper and Copper

Beryllium copper and copper may share some characteristics in name and properties, but they also differ in other important ways, and the two materials are not to be utilized reciprocally. Some of the differences between the two are:

- Electrical and Thermal Conductivity: The electrical conductivity of copper is 100%, and the levels of Beryllium copper are 15-30%. Beryllium copper’s low conductivity is rare when combined with its other desirable qualities.

- Hardness and Formability: Copper is known as gentler metal, while Beryllium copper is notable for its quality and strength. It can be formed into springs and complex shapes while still being the highest-strength copper-based alloy available.

- Uses: Copper is commonly used in goods where looks are important. You’ll find copper being used ornamentally. However, Beryllium copper is better used in internal components for its physical properties (strength and hardness).

How Safe is Beryllium Copper to Use

Beryllium copper, in solid form and as a component of completed products, poses no particular health hazards. Most manufacturing processes safely process Beryllium copper-containing materials when carried out properly on well-maintained machinery.

However, like many industrial minerals, Beryllium copper may pose a health concern if processed incorrectly. This can include:

- Developing serious lung diseases such as Chronic Beryllium Disease (CBD) as a result of inhaling beryllium-containing dust, mist, or fumes

- Berylliosis

- Lung cancer

The level of danger varies according to the product’s form, how it is processed and handled, and the amount of beryllium in the product.

How E-Fab Uses Beryllium Copper Safely

Beryllium copper is a critical material in circuit manufacturing for its electric and thermal conductivity capabilities. As mentioned previously, Beryllium copper can be very dangerous if processed improperly.

However, E-Fab’s engineers and laborers are skilled, experienced, and certified to handle Beryllium copper and other metals that can pose a health risk. We understand the risks and follow all proper procedures for working with beryllium—including participation in safety training.

In addition to safety training, E-Fab also ensures their workers are:

- Using personal protective clothing and equipment

- Respiratory Protection

- Limiting worker access to high-exposure areas

- General housekeeping in the facility where Beryllium copper is manufactured

- Hazard communication with teammates

- Record keeping of personnel

- Training on beryllium hazards

For almost 40 years, E-Fab has proudly delivered a variety of precision thin metal and flex circuit parts for customers across many industries and applications with the safety of their laborers in mind. These industries include:

- Tech Industries

- Aerospace Industries

- Telecommunication

- Military Defense

- Medical Sectors

Metals, including copper, stainless steel, aluminum, Beryllium copper, and more, can be photochemically etched, formed, bonded, and processed using high frequency by E-Fab.

E-Fab’s trained workforce leads clients through a project toward the best solution that precisely satisfies their demands, from the original concept to the delivery of a final product.

Our areas of expertise include the following:

- Design/engineering assistance

- Material selection/metrology

- CNC machining (including micromachining)

- Lamination

- Heat treating

- Electro and electroless plating

- Joining (including welding, wire bonding, soldering, and braising)

E-Fab uses industry-leading equipment and is an ISO 9001:2015 certified facility. Our innovative processes and expert staff ensure that every component we fabricate is of the highest quality. Learn more about our copper photochemical etching services here.

E-Fab Certifications

E-Fab ensures its customers quality products made by skilled laborers in a secure and safe environment and proudly made in the USA. Through this dedication, we have achieved recognition and several high-standard accreditations. We are ISO 9001:2015 certified, ITAR registered Conflict Mineral Free, and RoHS & REACH compliant.

Choose E-Fab for Your Beryllium Copper Needs

Beryllium copper’s characteristics make it the ideal material for various industries and applications. E-Fab uses sheets of Beryllium copper C172 00 Alloy 25 to manufacture different parts for your specific needs.

Our customers benefit from the following advantages when they partner with us for their precision thin metal and flex circuit needs:

- Design/engineering assistance (including optimizing for quality, manufacturability, and cost)

- Broad manufacturing capabilities (ranging from photochemical etching to finishing)

- Commitment to customer service (including signed nondisclosure agreements for proprietary ideas and products)

Contact E-Fab to Learn More About Beryllium Copper and Our Safety Measures

When deciding what metal to choose for your specific needs, it’s always important to be fully informed. E-Fab is available to help answer any questions about Beryllium copper or any metal for use.

With more than four decades of manufacturing experience and four L-3 Supplier of the Year Awards, E-Fab makes an excellent partner for almost any project. Our knowledgeable team assists clients with every step of the project, from consultation to design to manufacturing to delivery, and provides high-quality product solutions that precisely satisfy their requirements.

If you have further questions, please contact us to learn more.