Photochemical Etching is a leading processing method for producing thin metal parts used in thousands of end products that save lives, help us communicate, and drive innovation.

Engineers and designs refer to Photochemical Etching (PCE) by many names, including chemical milling, chemical machining, photochemical milling, photo etching, photochemical machining, and chemical etching. We call it Photochemical Etching at E-Fab.

It has many benefits, including higher customizability, cheaper tooling, and quicker turnaround, when used to produce precision thin metal parts.

E-Fab uses photochemical etching to manufacture a wide range of precision thin metal components for use in various industries. We can produce parts with complex or intricate geometries to tight tolerances at competitive prices.

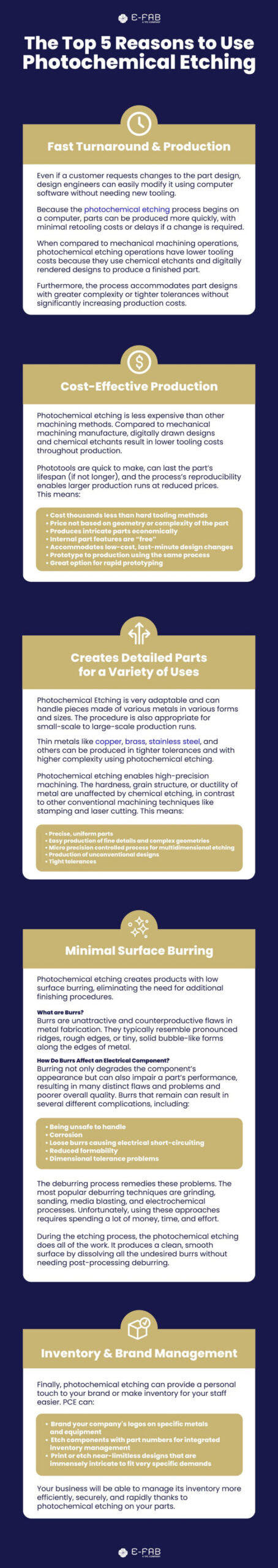

Here are the five advantages of Photochemical Etching and why it’s the right pick in precision manufacturing applications

Advantage of Photochemical Etching #1:

Fast Turnaround and Production

The digital nature of photochemical etching part designs allows for faster production of prototypes and production-quality pieces. Even if a customer requests changes to the part design, design engineers can easily modify it using computer software without needing new tooling.

Because the photochemical etching process begins on a computer, parts can be produced more quickly, with no retooling costs or delays if a change is required.

When compared to mechanical machining operations, photochemical etching operations have lower tooling costs because they use chemical etchants and digitally rendered designs to produce a finished part.

Furthermore, the process accommodates part designs with greater complexity or tighter tolerances without significantly increasing production costs.

Advantage of Photochemical Etching #2:

Cost-Effective Production

Photochemical etching is less expensive than other machining methods. Compared to mechanical machining manufacture, digitally drawn designs and chemical etchants result in lower tooling costs throughout production.

Phototools are quick to make, can last the part’s lifespan (if not longer), and the process’s reproducibility enables larger production runs at reduced prices. This means:

- Cost thousands less than hard tooling methods

- Price not based on geometry

- Produces intricate parts economically

- Internal part features are “free”

- Accommodates low-cost, last-minute design changes

- Prototype to production using the same process

Because photochemical etching uses chemical etchants and digitally produced designs to create a final item, tooling costs are low when compared to mechanical machining operations.

Furthermore, the technique may handle part designs with increased complexity or tighter tolerances without considerably growing production costs.

Advantage of Photochemical Etching #3:

Creates Detailed Parts for a Variety of Uses

Photochemical Etching is very adaptable and can handle pieces made of various metals in various forms and sizes. The procedure is also appropriate for small-scale to large-scale production runs.

Thin metals like copper, brass, stainless steel, and others can be produced in tighter tolerances and with higher complexity using photochemical etching.

Photochemical etching enables high-precision machining. The hardness, grain structure, or ductility of metal are unaffected by chemical etching, in contrast to other conventional machining techniques like stamping and laser cutting. This means

- Precise, uniform parts

- Easy production of fine details and complex geometries

- Micro precision controlled process for multidimensional etching

- Production of unconventional designs

- Tight tolerances

Advantage of Photochemical Etching #4:

Minimal Surface Burring

Photochemical etching creates products with low surface burring, eliminating the need for additional finishing procedures.

What are Burrs?

Burrs are unattractive and counterproductive flaws in metal fabrication. They typically resemble pronounced ridges, rough edges, or tiny, solid bubble-like forms along the edges of metal. The most commonly damaged material is sheet metal.

How Do Burrs Affect an Electrical Component?

Burring not only degrades the component’s appearance but can also impair a part’s performance, resulting in many distinct flaws and problems and poorer overall quality. Burrs that remain can result in several different complications, including

- Being unsafe to handle

- Corrosion

- Loose burrs causing electrical short-circuiting

- Reduced formability

- Dimensional tolerance problems

The deburring process remedies these problems. The most popular deburring techniques are grinding, sanding, media blasting, and electrochemical processes. Unfortunately, using these approaches requires spending a lot of money, time, and effort.

During the etching process, the photochemical etching does all of the work. It produces a clean, smooth surface by dissolving all the undesired burrs without needing post-processing deburring.

Advantage of Photochemical Etching #5:

Inventory and Brand Management

Finally, photochemical etching may provide branded parts with your company logos, components with etched part numbers for integrated inventory management, and components with etched part numbers for integrated inventory management.

Your business will be able to manage your inventory efficiently, securely, and rapidly thanks to photochemical etching on your parts.

Choose E-Fab for Your Photochemical Etching Needs

We’ve been using photochemical etching since our beginnings, producing thin metal parts in various materials for the telecommunications, defense, medical, and electronics industries.

At E-Fab, we turn a variety of metal and composite materials into parts for a wide range of industries using photochemical etching and various wet machining technologies.

From the initial concept through the delivery of the finished product, E-Fab’s skilled team guides clients through a project toward the finest solution that precisely meets their needs.

Our areas of expertise include

- Design/engineering assistance

- Material selection/metrology

- CNC machining (including micromachining)

- Lamination

- Heat treating

- Electro and electroless plating

- Joining (including welding, wire bonding, soldering, and braising)

E-Fab uses industry-leading equipment and is an ISO 9001:2015 certified facility. Our innovative processes and expert staff ensure that every component we fabricate is of the highest quality. Learn more about our photochemical etching services here.

Contact E-Fab to Learn More About Photochemical Etching

When deciding what metal to choose for your specific needs, it’s always important to be fully informed. E-Fab is available to help answer any questions about photochemical etching.

With more than four decades of manufacturing experience and four L-3 Supplier of the Year Awards, E-Fab makes an excellent partner for almost any project. Our knowledgeable team assists clients with every step of the project, from consultation to design to manufacturing to delivery, and provides high-quality product solutions that precisely satisfy their requirements.

If you have further questions, please contact us to learn more.