With industry-leading expertise in precision metal parts, the team at E-Fab understands the significant impact unwanted electromagnetic signals can have on electronic components and devices.

As experts in RFI (Radio Frequency Interference) and EMI (Electromagnetic Interference) Shielding, we’ve put together all the information you need to confidently select materials and design for RF shielding applications.

What is Radio Frequency Shielding?

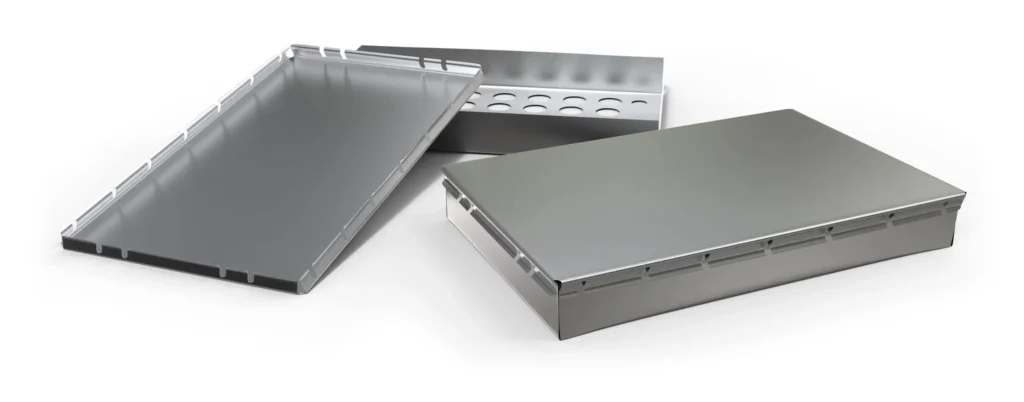

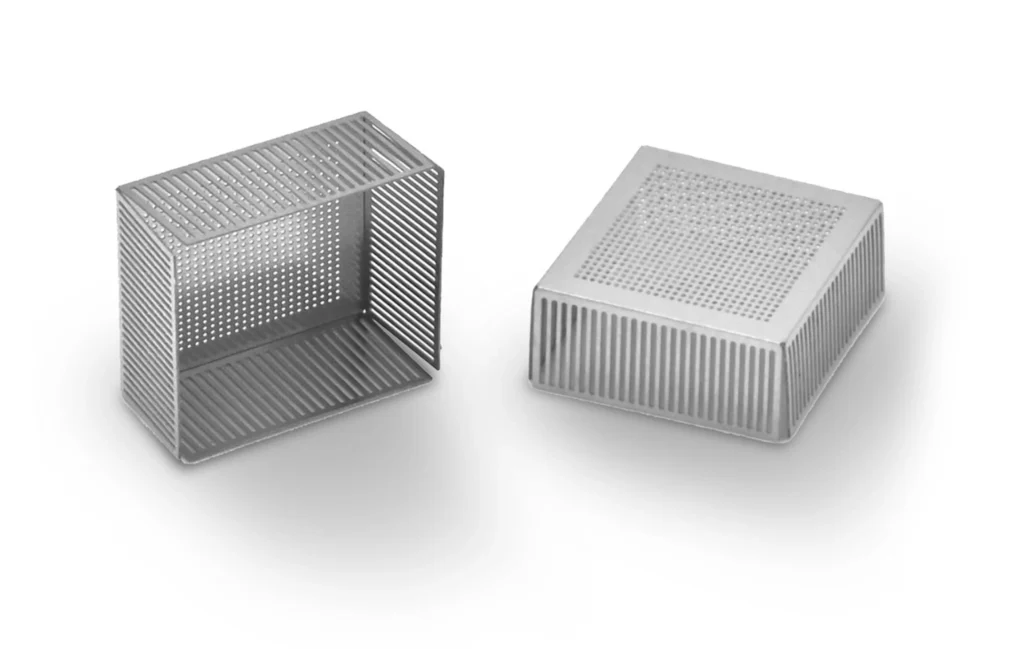

Radiofrequency shielding, also known as RF shielding, blocks electromagnetic interference (EMI). Often made from metal, it blocks or reduces the electromagnetic signals from radio frequencies that can interfere with electronic devices and damage your valuable equipment.

RF shields are critical components in protecting sensitive equipment from radio frequency interference (RFI), which can disrupt the performance of circuits and communication systems. By containing or blocking unwanted RF signals, these shields ensure that devices operate without interference, maintaining their integrity and reliability in critical applications.

Explore the critical role of RF Shielding in medical equipment.

What Materials Are Best for EMI/RFI Shields?

We know that RF signals can interfere with certain electronic devices, but what materials provide the strongest shielding?

The strength of the shield depends on several factors, including the thickness and composition of the material used for shielding. Based on the application of your equipment, you’ll have to choose the perfect material depending on weight, conductive properties, or even cosmetic reasons.

The best RF shielding materials for EMI/RFI shields are typically conductive and magnetic materials like copper, aluminum, brass, and specialized alloys. These metals are excellent at absorbing and redirecting electromagnetic waves due to their conductivity, making them ideal for shielding effectiveness against radiofrequency interference. Copper, for example, is highly conductive, offering strong protection against both RF and low-frequency magnetic interference, while aluminum is lightweight and cost-effective for RF shielding material applications.

The right shielding material depends on the specific frequencies and environmental factors the shield will encounter, ensuring optimal performance in blocking unwanted signals.

Picking the right material is crucial. Read on to learn more about each material and find the right one for your part.

Copper

Copper is a good conductor of electricity, heat, and electromagnetic radiation. It is also a great conductor of sound waves, light photons, and radio waves while blocking radio frequencies. Copper is the typical choice for MRI machines and other medical equipment.

Working with copper presents an array of benefits. Some of these include:

- Easy to solder, braze, and weld

- Inexpensive

- Easy to process

- Highly conductive (electric and thermal)

- High flexibility/malleability

- Will stick to nearly any finish, including gold

- Conforming coatings can provide anti-oxidation characteristics for PCB applications

When choosing conductivity as your main criterion for an EMI/RFI shield material, copper is the best option because it conducts so many different types of energy and it holds up well to changing temperatures and altitudes.

When choosing an appropriate material for EMI/RFI shields, it is essential to consider extreme conditions. Copper is often our first choice in these situations.

Read more about how E-Fab uses copper and copper alloys.

Brass

Brass is an alloy of copper and zinc. It is a good EMI/RFI shield material used in many applications, including medical devices, electrical contacts and connectors, RF connectors and solder joints, and relays.

There are many benefits of working with brass, including

- Affordability

- Electrical resistance

- Corrosion resistance

- Wear resistance

- High-temperature tolerance

- Formability and machinability

- Compatibility with finishing treatments

Read more about how E-Fab uses brass.

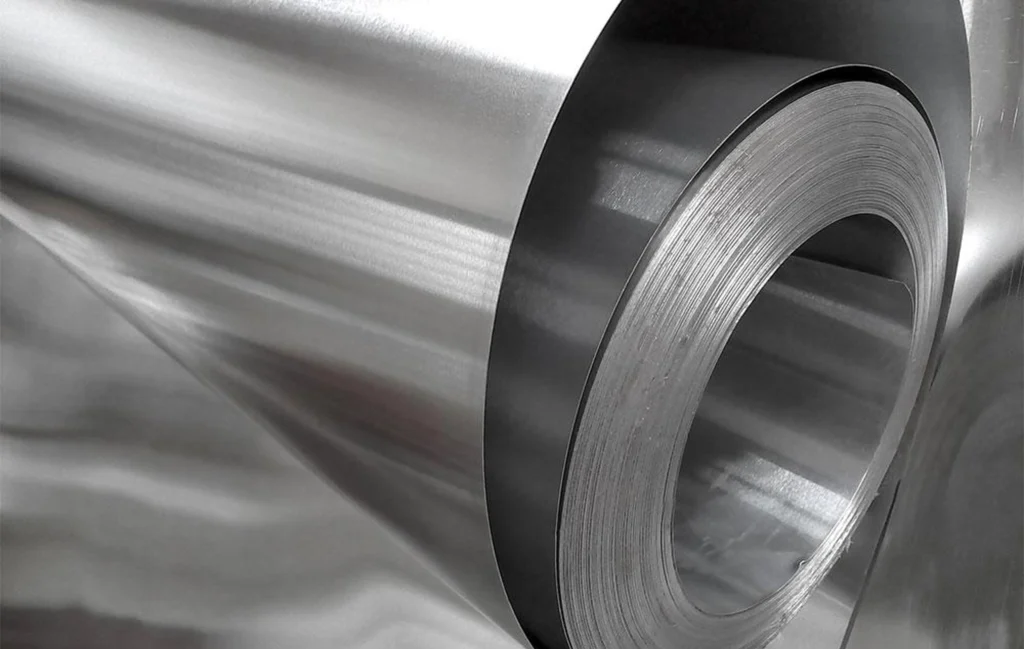

Aluminum

Aluminum is a good conductor of electricity and heat, which makes it an ideal choice for EMI/RFI shielding. It is lightweight and strong (it can withstand greater pressure than steel) but also inexpensive.

Aluminum’s low density allows for thinner sheets with the same strength as thicker sheets made from other metals. This means you can save money using aluminum shielding instead of heavier metals like lead or iron.

Aluminum is one of the top choices for commercial and industrial parts, components, and products. This lightweight metal is strong, reliable, and versatile. It also comes in multiple grades that offer corrosion and fatigue resistance and may be anodized when required.

The main benefits of working with aluminum include:

- Affordability

- Versatility

- Durability

- Lightweight

Read more about how E-Fab uses aluminum.

Gold

Gold is an excellent metal for EMI/RFI shields, especially in applications where high frequencies are in play. We use gold for plating.

Gold’s conductivity increases with frequency, which makes it especially effective in applications where radio frequencies are used as energy sources (such as in cell phones or WiFi routers).

Lastly, because gold resists corrosion and oxidation and has excellent thermal properties (it doesn’t melt until 1,064 °F), it lasts longer than other materials under harsh environmental conditions like moisture exposure or high temperatures like those found inside electronic devices.

Nickel

Nickel and Nickel Alloys make excellent EMI/RFI shielding materials for low-frequency applications. It is a durable material that stands up to corrosion and features excellent mechanical properties such as strength, high-temperature tolerance, and versatility across several industries.

What Materials to Avoid

It’s not always black and white when choosing a suitable material for EMI/RFI shields. Some materials can block radio frequencies across the electromagnetic spectrum, but they might not be the best long-term choice. These metals, such as steel, zinc, and magnesium, may face durability issues and unwanted reactions when in contact with other metals, especially over the duration of continuous radiofrequency interference, which can degrade their effectiveness over time.

The Different Ways You Shape and Make Shields

There are several key methods used to form or shape RF shields, each suited to different project needs based on production volume and design complexity.

- Machine Forming: This method uses automated machines to bend or shape metal into precise forms, making it ideal for large production runs that require consistent, repeatable results. It offers high precision and speed, ensuring uniformity across a large batch of RF shields.

- Stamping: Stamping is a cost-effective option for high-volume production. Using a die, this method can quickly form RF shields into specific shapes with tight tolerances. Stamping is especially useful when producing complex geometries in bulk, as large production quantities offset the initial tooling costs.

- Hand Forming: Hand forming allows for greater flexibility for small production runs or highly specialized RF shields. Skilled technicians manually shape the material, which is ideal for custom or prototype projects that need unique dimensions or adjustments that are difficult to achieve with automated methods.

Each method offers advantages depending on whether the project requires a high-volume production run or a more custom, low-volume approach.

E-Fab’s RFI and EMI Shielding Processes and Advantages

As trusted experts in RF shielding, we can design and manufacture customized solutions that safeguard against electromagnetic interference and ensure uninterrupted functionality.

We are:

Shielding Materials Experts: We deeply understand various shielding materials, their properties, and their effectiveness in attenuating or reflecting electromagnetic waves. This includes conductive metals, metal alloys, conductive coatings, and composite materials.

Designers and Engineers: Our extensive design solutions include shielding enclosures, components, and structures that provide effective electromagnetic shielding. Our design process considers essential aspects such as enclosure geometry, material selection, gasketing, grounding, and filtering techniques.

Compliant: We understand the relevant industry standards and regulations for electromagnetic compatibility (EMC) and ensure our shielding solutions comply.

Work With the Experts at E-Fab

Boasting industry-leading expertise in RFI (Radio Frequency Interference) and EMI (Electromagnetic Interference) Shielding, we can help mitigate the impact of RFI and EMI to safeguard critical systems, enhance signal integrity, and maintain overall functionality.

With deep knowledge of Electromagnetic Theory, we understand the complexities of electromagnetic fields, electromagnetic wave propagation, interference mechanisms, electromagnetic noise, and the behavior of electromagnetic waves in different materials and environments.

Our experience and expertise in RFI and EMI shielding span a wide range of specialized industries, applying proven techniques to industries and applications, such as aerospace, telecommunications, medical devices, automotive, or military, where electromagnetic compatibility is critical.

Don’t take any chances when picking the right materials. E-Fab’s engineers, materials experts, and quality assurance professionals can help select the material best for your project.