Whether you are refining a prototype or preparing to ramp up production, E-Fab delivers custom metal mesh screens from a variety of material thickness options, manufactured with high precision, while maintaining high performance and durability. Our experts work directly with engineers to create custom mesh components tailored to your exact specifications, supporting the most critical applications in the aerospace, defense, medical, electronics, and filtration industries. E-Fab is committed to meeting the specific needs of our customers, ensuring that each product is customized to their exact requirements.

Still in the design phase? Let’s get you connected with one of our experts to familiarize ourselves with your goals.

Ready for full-scale production? Let’s get you a quote today so we can support your mission!

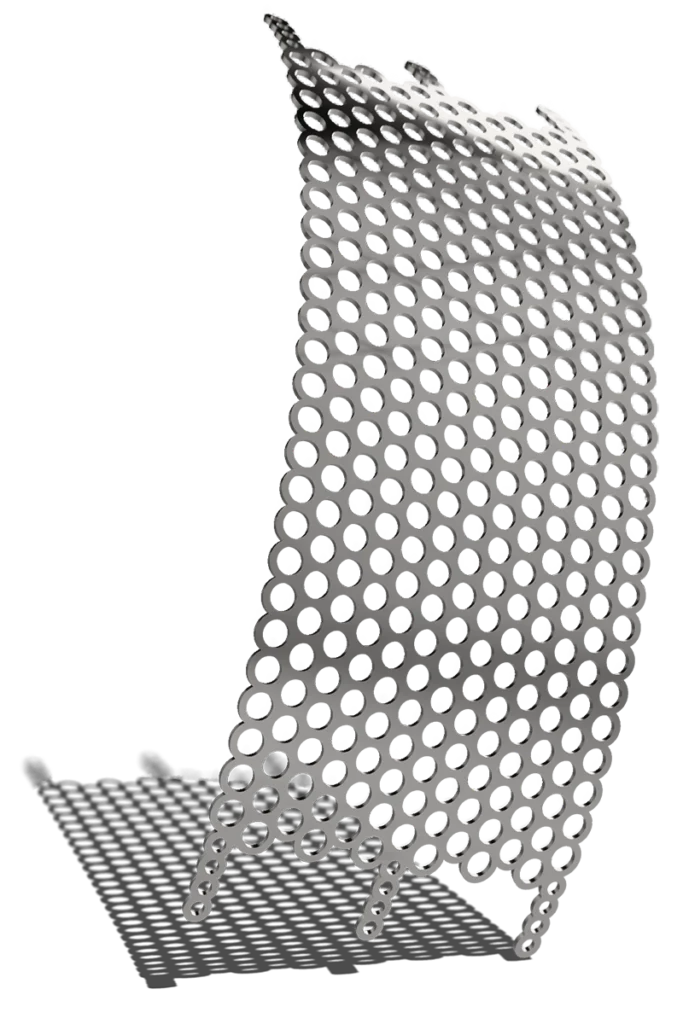

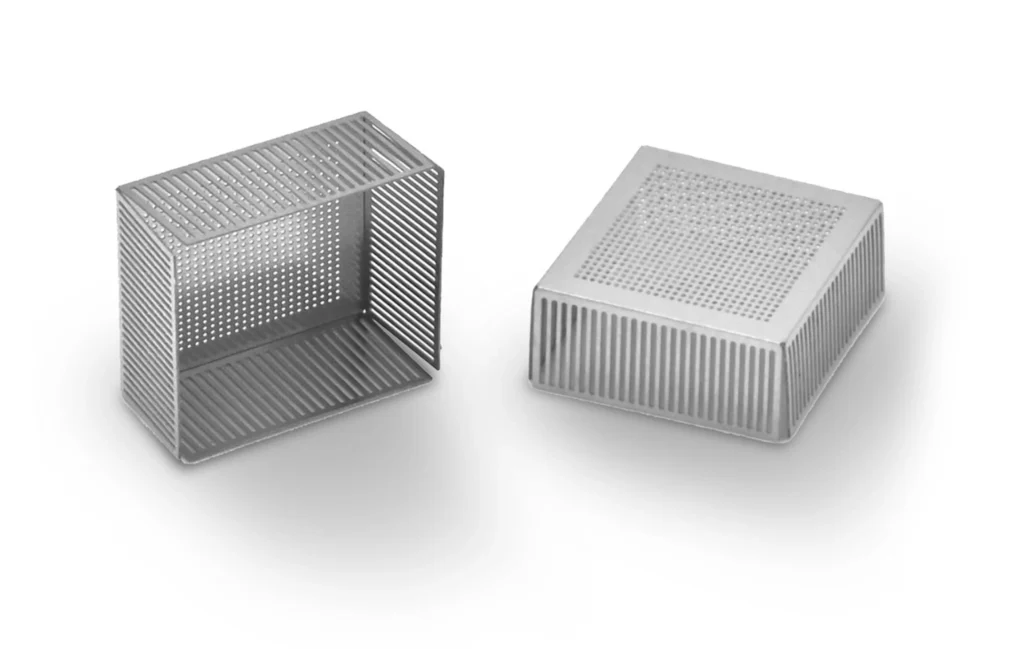

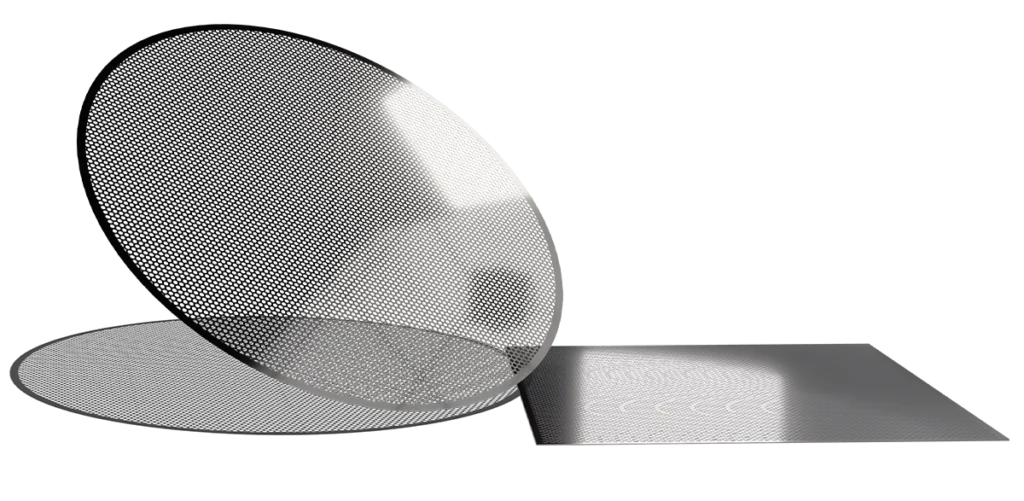

Custom mesh screens from E-Fab are engineered for high-precision applications where accuracy, consistency, and performance are critical. These metal screens feature intricately patterned apertures and are used in demanding environments for EMI shielding, filtration, flow control, and more. Unlike woven or welded mesh, E-Fab’s process produces metal mesh components that are completely free from mechanical stress, warping, or burrs, ultimately ensuring optimal reliability and performance.

One of the primary advantages of our custom mesh screens is the level of precision they offer. With aperture sizes as small as 25 microns, E-Fab delivers micro-scale accuracy that’s essential for applications like medical filtration, inkjet printing, and fuel delivery systems. The clean, burr-free apertures promote superior flow control and filtration performance, while the flat, distortion free form ensures consistent fit, form and function within extremely tight tolerances.

Design flexibility is another key benefit. Our advanced manufacturing capabilities allow for the creation of complex or irregular aperture patterns that aren’t possible with traditional woven or stamped mesh. Whether you need square, round, slotted, or entirely custom geometries, E-Fab can deliver tailored solutions that meet your exact engineering requirements, allowing engineers to design with less limitations in comparison to traditional methods.

From prototyping to production, E-Fab provides custom metal mesh screens that outperform traditional welded or woven alternatives. Chemically etched mesh offers cleaner, more precise apertures with no fraying, warping, or overlapping wires, which eliminates common issues found in woven screens. Unlike welded mesh, which can introduce heat distortion and limited pattern flexibility, etched mesh maintains flatness and dimensional accuracy even at micron-level tolerances. This results in better flow control, more reliable filtration, and seamless integration into precision assemblies.

| FEATURE | DETAILS |

| Aperture Size | > 25 Microns |

| Thickness Range | 0.0005″ – 0.040″ (0.013mm – 1.016mm) |

| Pattern Types | Square, Round, Slotted, Hexagonal, Irregular and Custom |

| Materials | Stainless Steel, Copper, Titanium, Molybdenum, etc. |

| Additional Options | Surface Plating, Frames, Multi-Layer Mesh, Step-Etching |

| Volume | Prototyping to High-Volume Production |

| Quality Certifications | AS9100 and ISO9001:2015 Certified, ITAR Registered and RoHS Compliant |

| Aperture Size | > 25 Microns |

| Thickness Range | 0.0005″ – 0.040″ (0.013mm – 1.016mm) |

| Pattern Types | Square, Round, Slotted, Hexagonal, Irregular and Custom |

| Materials | Stainless Steel, Copper, Titanium, Molybdenum, etc. |

| Additional Options | Surface Plating, Frames, Multi-Layer Mesh, Step-Etching |

| Volume | Prototyping to High-Volume Production |

| Quality Certifications | AS9100 and ISO9001:2015 Certified, ITAR Registered and RoHS Compliant |

EMI/RFI Shielding used in electronics and aerospace applications

Flow and particle control, inkjet, and fuel spray nozzles

With over 40 years of experience, E-Fab stands out as a trusted partner for custom metal mesh screens, delivering superior precision and performance for critical applications. Our chemical etching process achieves tighter tolerances and cleaner edges than punched, stamped, or woven mesh, resulting in improved flow control, filtration efficiency, and EMI shielding. With aperture sizes down to 25 microns and complete design flexibility, we can create custom shapes, sizes, thicknesses, and geometries to meet your exact specifications.

Our team supports projects from concept to production, with in-house engineering, rapid prototyping, and expert design collaboration. As an AS9100 certified and ITAR registered U.S. manufacturer, E-Fab ensures the highest quality standards, fast turnaround times, and a secure, reliable domestic supply chain which supports the most critical infrastructure of our most demanding industries.

Whether you know exactly what you need, or you could use some additional assistance, E-Fab is positioned to support your custom metal mesh screen needs and our robust knowledge and experience in the industry give you a head start to achieve your goals.

We look forward to supporting your vision and the opportunity to work together, Request a Quote today or speak with a Mesh Master to get the conversation started.

Our team supports projects from concept to production, with in-house engineering, rapid prototyping, and expert design collaboration. As an AS9100 certified and ITAR registered U.S. manufacturer, E-Fab ensures the highest quality standards, fast turnaround times, and a secure, reliable domestic supply chain which supports the most critical infrastructure of our most demanding industries.