To help design engineers enhance their design and manufacturing process, we’ve put together some practical and comprehensive design tips for metal etching.

Precision forming is a crucial part of modern metal manufacturing, enabling the production of complex and high-performance components. In this age of innovation and efficiency, precision forming has revolutionized the way metal components are crafted, delivering precise, intricate parts that can meet the most stringent specifications.

The specialized metal forming process involves accurately shaping metal materials, ensuring minimal material waste and impeccable dimensional consistency. It allows manufacturers to craft components with intricate geometries, exceptional mechanical properties, and tight tolerances by harnessing advanced techniques like press brake forming, roll forming, and hydroforming.

At E-Fab, we’re experts at forming the exact part from metal materials that work with existing components or detailed design specifications. Our manufacturing experts perform a wide range of precision forming techniques and processes, delivering precision metal products. Every piece we produce is carefully finished and put through an exacting Quality Assurance process before delivery.

Forming creates precision metal products

Precision forming has fast become a cornerstone of modern manufacturing, allowing manufacturers to create intricate and complex parts by shaping metal materials with exceptional accuracy and meticulous detail.

Using advanced techniques like press brake forming, slide forming and hydroforming, and innovative roll forming technologies, precision forming achieves tight tolerances and intricate geometries, resulting in components with superior structural integrity and consistent dimensional characteristics.

Precision metal forming not only enhances the overall structural integrity of products but also contributes to the reduction of post-processing requirements.

Enabling the production of high-performance components that meet stringent specifications and drive technological innovation, precision forming is used for a myriad of industries, ranging from aerospace and automotive to electronics and healthcare.

The Basics of Precision Forming

Precision forming has fast become the preferred forming method in metal manufacturing, but what sets it apart? Unlike general forming, which focuses on basic shaping with acceptable tolerances, precision metal forming employs advanced techniques and value added processes, such as computer-controlled machinery and finely-tuned tooling, to achieve extremely tight tolerances and intricate geometries. The level of detail it can deliver ensures consistent dimensional attributes across multiple components, reducing variations and enhancing overall product quality.

Commonly utilized materials

Commonly utilized materials include strong, corrosion-resistant stainless steels, which are perfect for producing medical instruments and aerospace components.

Aerospace-grade aluminum alloys are also widely used due to their lightweight properties and are commonly found in aircraft structures.

Titanium alloys, renowned for their exceptional strength-to-weight ratio, are indispensable in both aerospace and medical implant applications while advanced materials like composites are also integrated into precision forming processes for more specific applications.

The ability to tailor the material selection to the precise needs of a component underscores the versatility of precision forming techniques in accommodating a wide array of materials across diverse industries.

Here at E-Fab, we use a range of quality materials that include:

- Beryllium Copper

- Stainless Steel Alloys

- Aluminum Alloys

- Thin Sheet Metals and more

Key benefits of precision metal forming

The main benefit of precision metal forming lies in the ability to achieve unparalleled dimensional precision, ensuring that components are crafted to exact specifications with minimal deviations.

This level of accuracy enhances the overall functionality of products and reduces the need for costly rework or adjustments.

Another key benefit is that precision-formed metal components boast exceptional durability, as the controlled deformation process aligns the metal’s crystalline structure, enhancing its mechanical properties and fatigue resistance. This leads to longer-lasting components that remain reliable in even the harshest environments.

The Precision Forming Process

With a goal to deliver precision parts with intricate geometries and tight tolerances, the precision forming process relies on cutting-edge machinery, computer-controlled systems, and bespoke tooling that all work together in harmony to push the boundaries of what’s achievable in modern manufacturing.

Accuracy and durability are the hallmarks of well-designed and manufactured parts produced by precision metal forming. E-Fab’s expert forming capability starts with CAD modeling by our engineering team. From there, our manufacturing floor, where engineers take machine code to form precise metal parts to exacting standards and specifications.

When it comes to precision forming, choosing the right material is essential. Boasting decades of experience working with a variety of metals/materials, the E-Fab team are there to recommend the best choice depending on the final requirements.

The Techniques Used in Precision Forming

Heat Treating

Heat treating plays a pivotal role in the precision forming process, responsible for improving the performance and durability of precision-formed metal components. By subjecting the formed metal to controlled heating and cooling cycles, mechanical properties such as hardness, strength, and ductility are enhanced – improving wear resistance and fatigue strength. Through processes like annealing, quenching, and tempering, heat treating relieves internal stresses accumulated during forming, mitigates distortion and refines the material’s grain structure for optimal resilience.

Bending

A fundamental technique within the precision forming process, bending is used to shape metal materials to exacting specifications. With its role extending beyond just changing the shape of the metal, bending is a conduit for achieving intricate geometries and angular precision crucial for component functionality. Manufacturers can bend metal with remarkable accuracy by skillfully applying controlled force through methods like press brake forming, crafting complex shapes that traditional methods would struggle to replicate. This process ensures that components align seamlessly within larger assemblies and minimizes the need for post-processing adjustments, saving valuable time and resources.

Press Forming

Crucial in producing reliable and accurate components, press forming transforms flat metal sheets into three-dimensional shapes with unparalleled precision. With controlled force and intricate tooling, press forming can achieve complex contours, tight tolerances, and consistent dimensions critical for high-performance components. By harnessing hydraulic or mechanical presses and precisely designed dies, press forming ensures exacting geometries and minimizes material waste through efficient material utilization.

The Processes Used in Precision Metal Forming

Drilling

Drilling in precision metal forming is a precision-enhancing technique that complements the intricacies of shaping metal components. Used to carve out holes with unparalleled accuracy, it contributes to the delivery of intricate geometries, exacting hole diameters, and optimal positioning critical for component functionality. The benefits of drilling include reduced assembly complexities, improved alignment in multi-part structures, and streamlined integration of additional components. By leveraging precision drills and advanced machinery, manufacturers ensure that holes are impeccably placed and dimensionally consistent, minimizing deviations and enhancing the overall quality of precision-formed components.

Finishing

This meticulous process encompasses the delicate tasks of polishing, deburring, and surface treatment, ensuring that every contour and edge delivers the precision required for the project. An essential step between precision forming and the final product, finishing refines surfaces to eliminate imperfections, sharp edges, and inconsistencies that might compromise functionality or aesthetics. It not only enhances the tactile and visual appeal of components but also minimizes potential points of weakness, thereby improving overall durability and reducing the risk of premature failure.

Coating & Painting

Crucial to the longevity and performance of components, the intricate process of coating & painting involves applying protective layers that shield components from environmental stressors such as corrosion, abrasion, and chemical exposure. More than just improving the visual aspect of a component, coating and painting form a robust defense mechanism, ensuring that the precision-formed components endure the rigors of real-world applications. These coatings can range from corrosion-resistant treatments like galvanization to advanced powder coatings that enhance resistance to wear and impact. By enveloping precision-formed metal with these protective layers, manufacturers not only enhance the durability and lifespan of their products but also bolster their ability to withstand the harsh environments they need to work in.

The Importance of Quality Assurance in Precision Metal Forming

Playing a crucial role in precision metal forming, quality assurance is relied upon by manufacturers to ensure that every crafted component adheres to the most exacting and stringent standards.

Encompassing comprehensive inspections, rigorous measurements, and stringent testing protocols, quality assurance prevents defects and identifies potential problems at the earliest possible part of the process.

At E-Fab, our clients get the peace of mind knowing that we send each piece through careful finishing and an exacting Quality Assurance process before delivery.

Apply the shared design tips to your manufacturing processes and dive deeper into the ever-evolving world of metal etching to see what’s truly possible for your business.

E-Fab's Forming Expertise

We are experts at forming the exact part from metal materials that work with existing components or detailed design specifications.

Our manufacturing experts perform a wide range of precision forming techniques and processes, delivering accurate and reliable parts.

Experience The E-Fab difference

E-Fab’s expert forming capability has fast built a reputation for delivering accurate and durable metal components. To do this, we’ve developed specialist processes and techniques that include:

Dimpling

A proprietary forming process developed at E-Fab used to ensure electrical contact is available on the part surface.

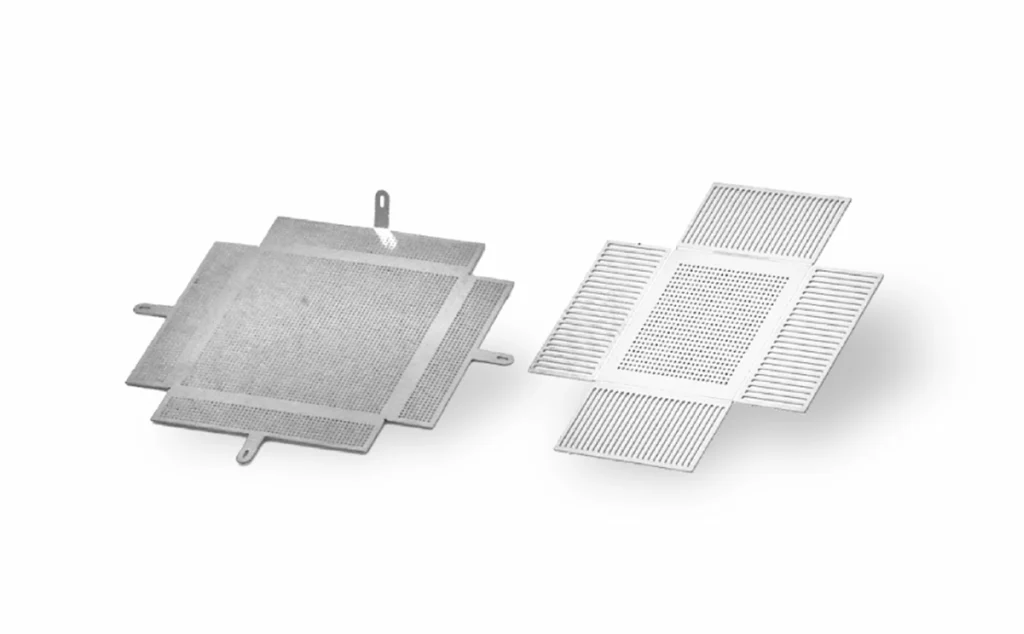

Shield Forming

We manufacture materials into precise shields for use in highly sensitive applications.

Waveguide Forming

A technique we use in complex seamless structures to direct and control electromagnetic energy.

Angle Forming

A technique we use when maximum alloy strength is required for a part.

A preferred partner for precision metal parts, we serve a wide range of industries, that include Aerospace, Military, Defense, Energy, Fuel Cells, Medical, Microwave, Semiconductor, Telecommunications, Colleges, Secondary Schools, Federal Agencies, State Government, Agriculture, Automotive/Transportation/Mobility, Electronics, Instrumentation & Control Systems, Manufacturing and Technology.

As a proud member of The Partner Companies group of specialty manufacturers, our network shares experience, materials, capabilities, and expertise to serve the defense, aerospace, medical, telecommunications, semiconductor, and renewable energy industries.

For reliable, accurate and durable precision metal forming, reach out to the team at E-Fab and discover the difference for yourself.