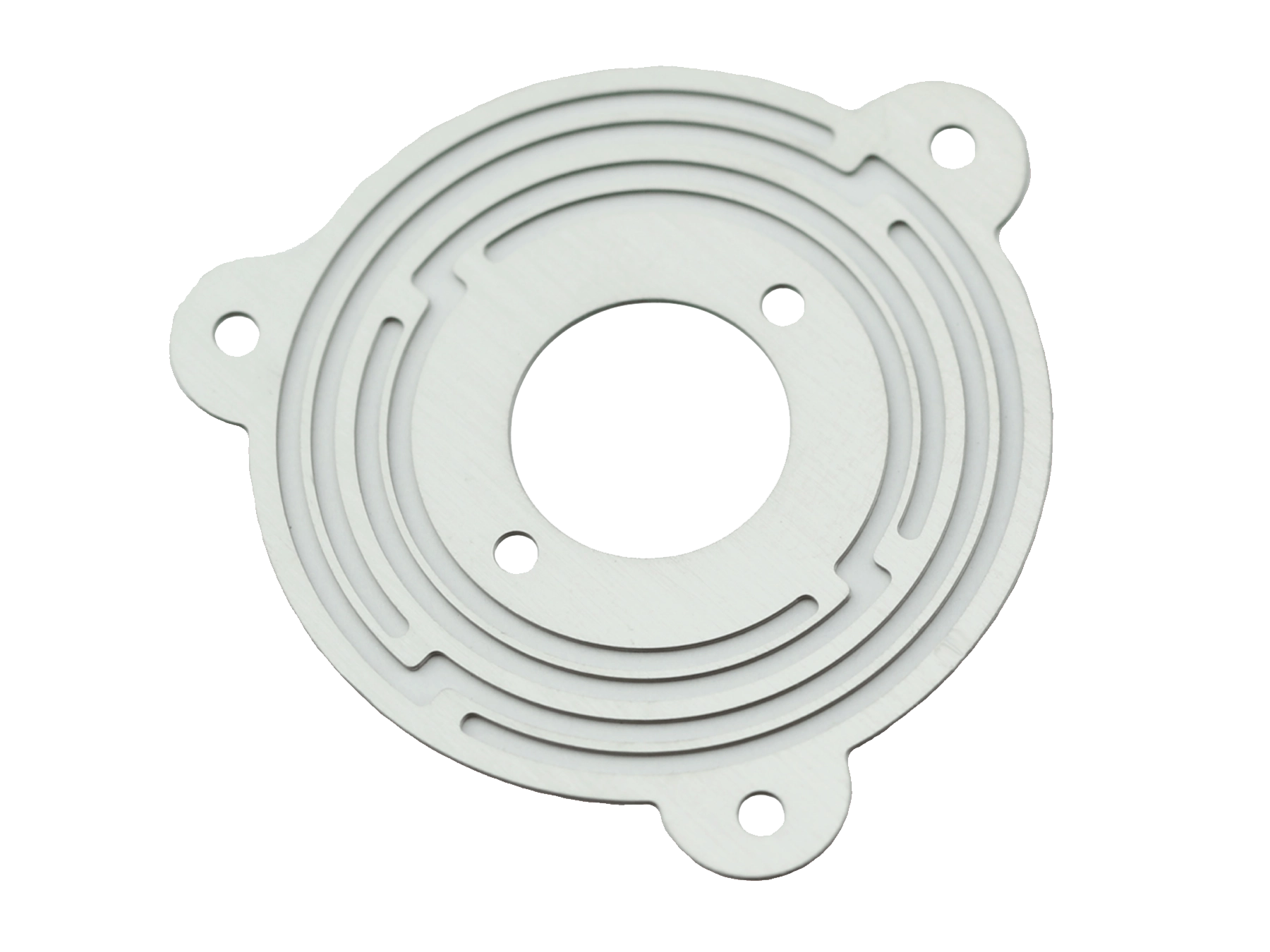

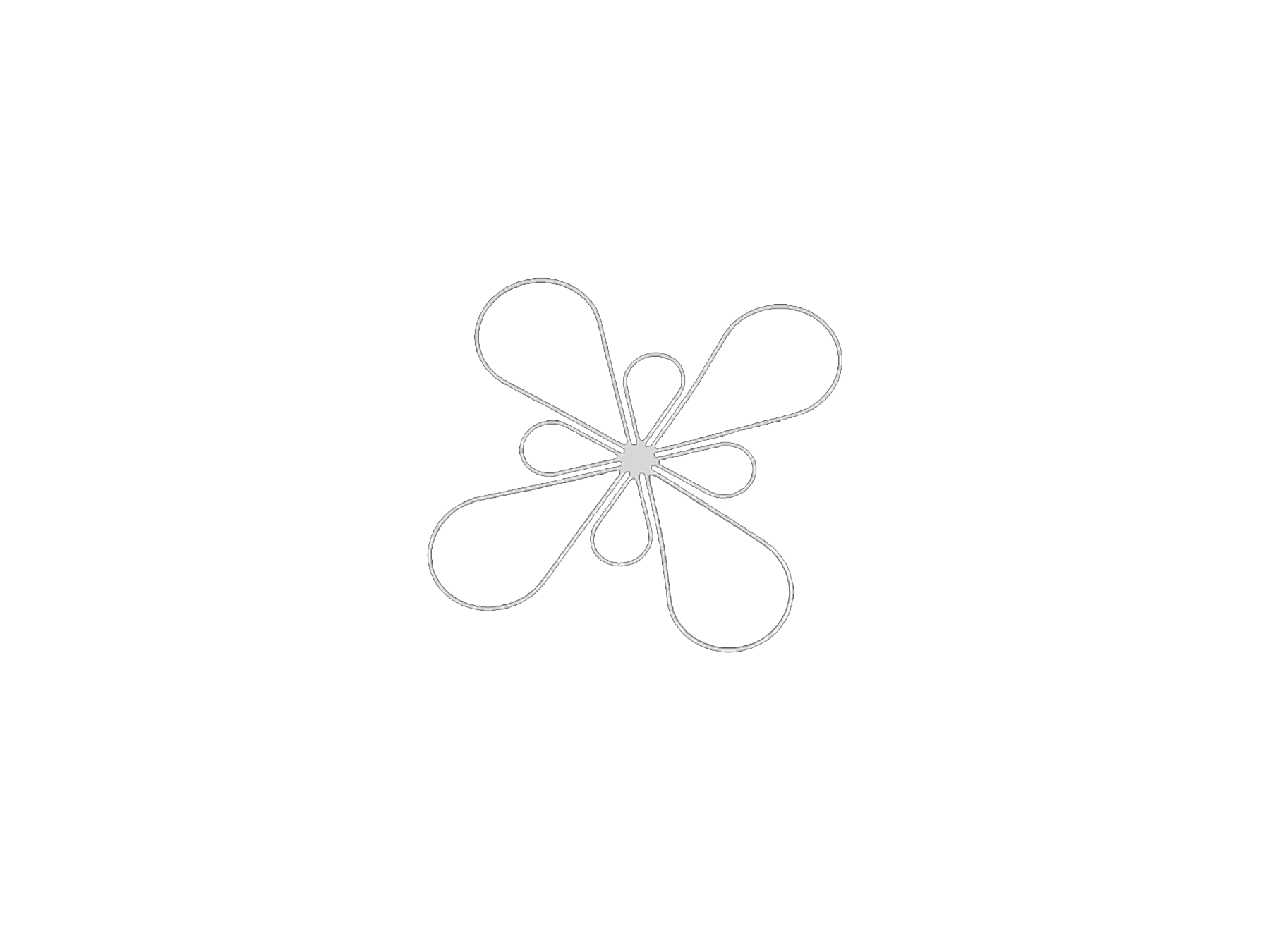

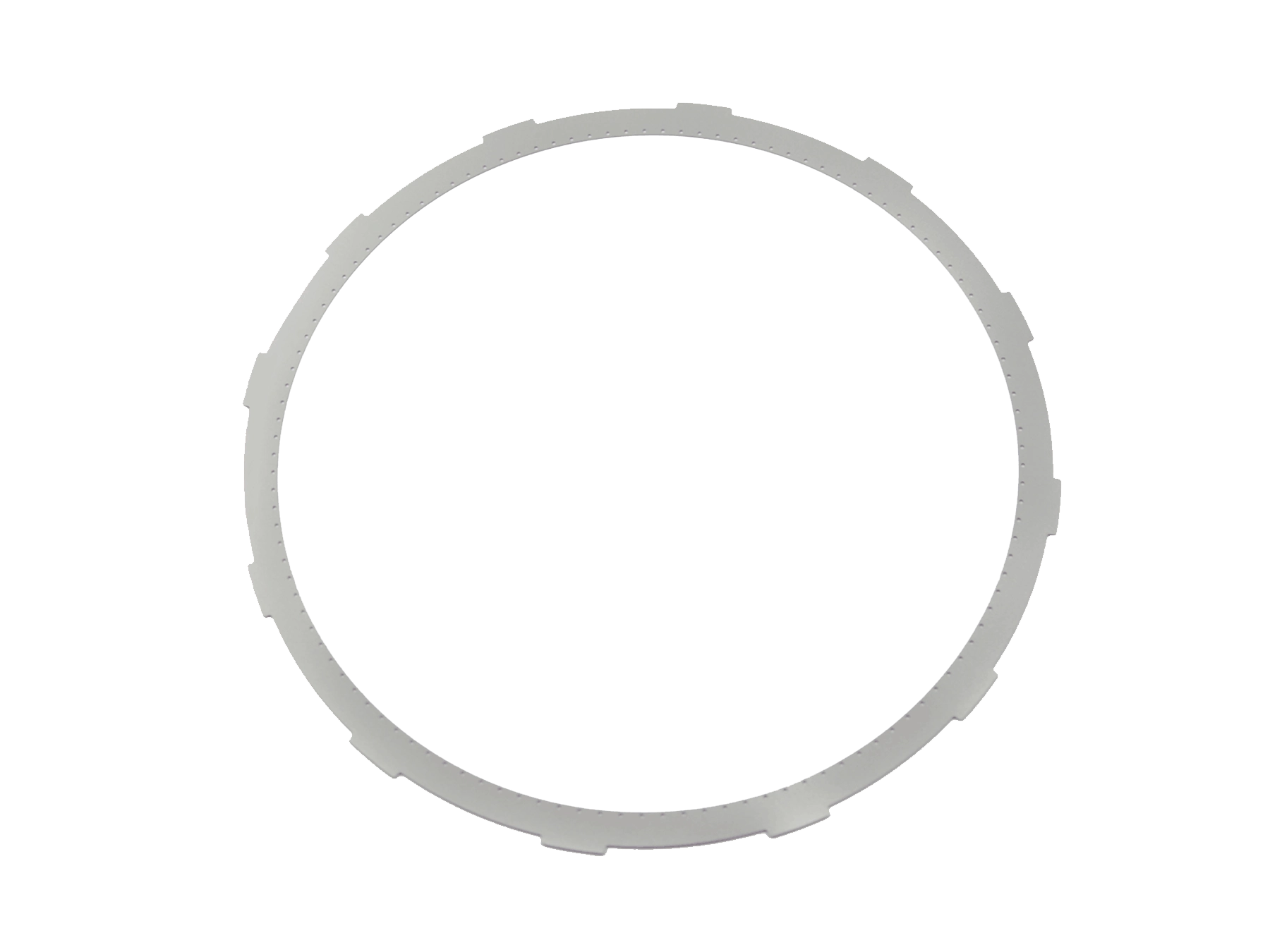

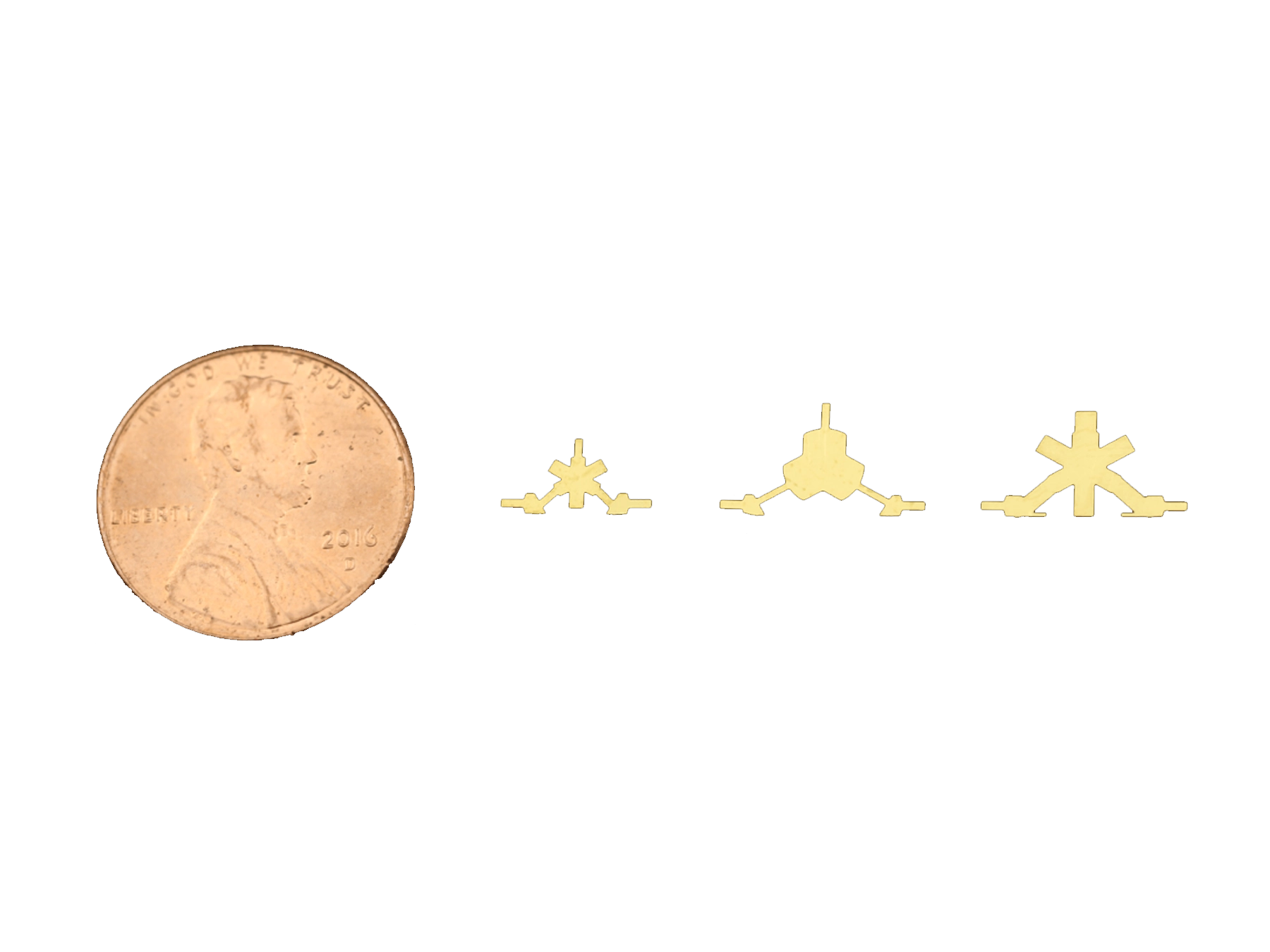

E-Fab is a leading provider of photochemical etching manufacturing services, an ideal process for precision thin metal parts. Photochemical etching is also known as photochemical machining (PCM) and chemical blanking.

Photochemical etching enables us to deliver parts with complex or intricate geometries and tight tolerances for customers in the telecommunications, defense, medical, and electronics industries.

There are several benefits of utilizing photochemical etching to produce precision thin metal parts.

Digitally rendered designs and chemical etchants equal reduced tooling costs during production compared to mechanical machining manufacturing.

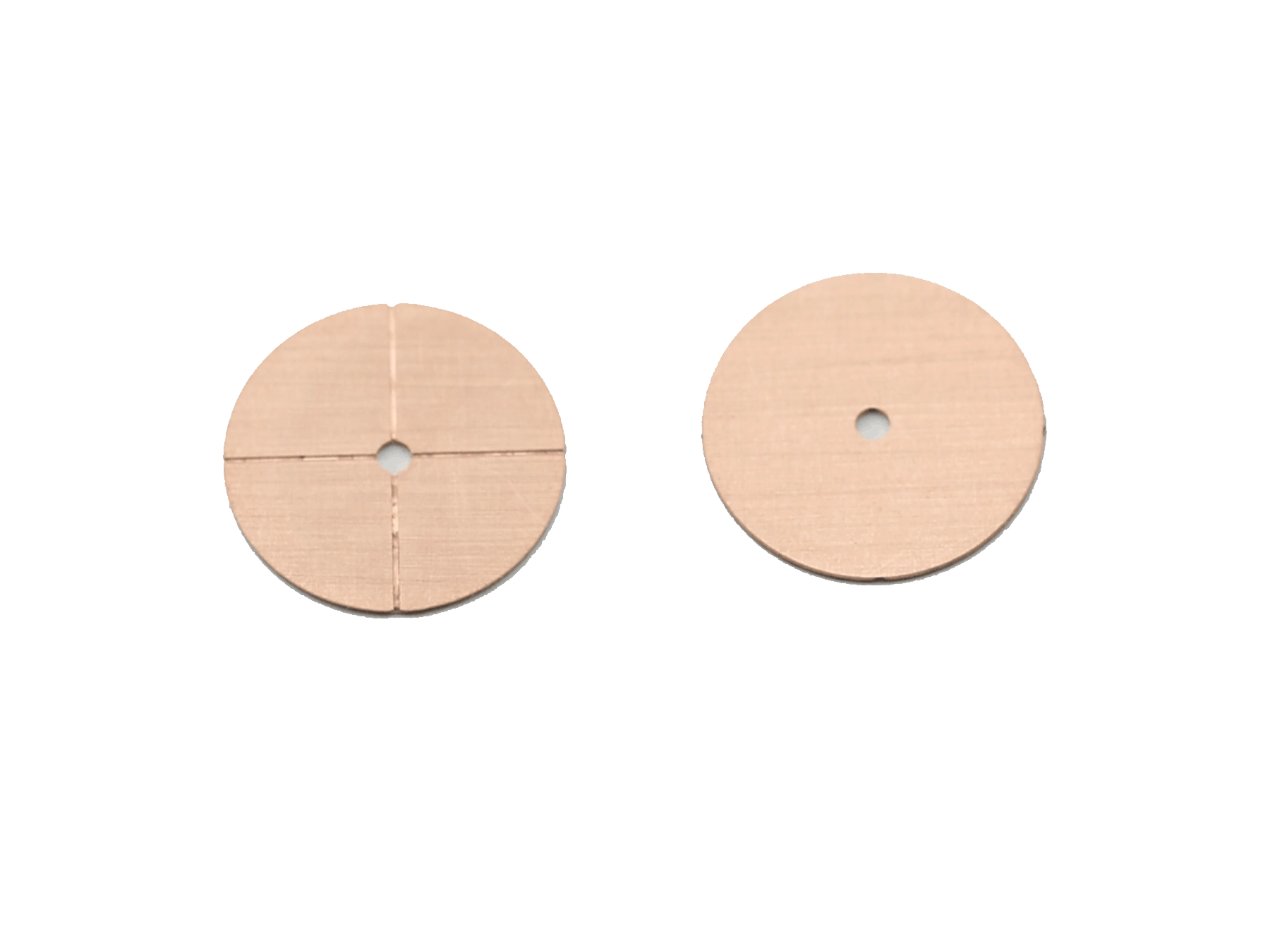

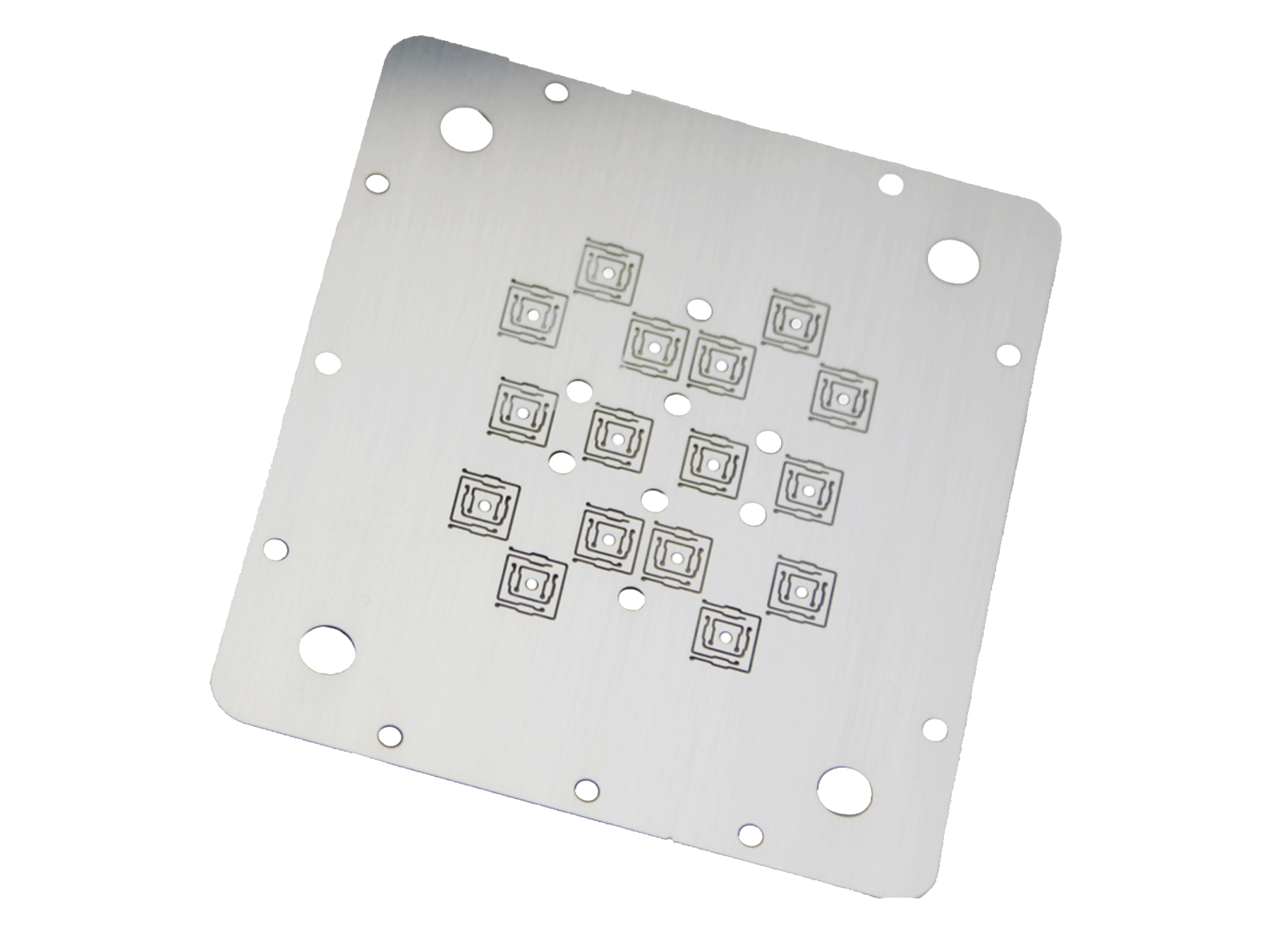

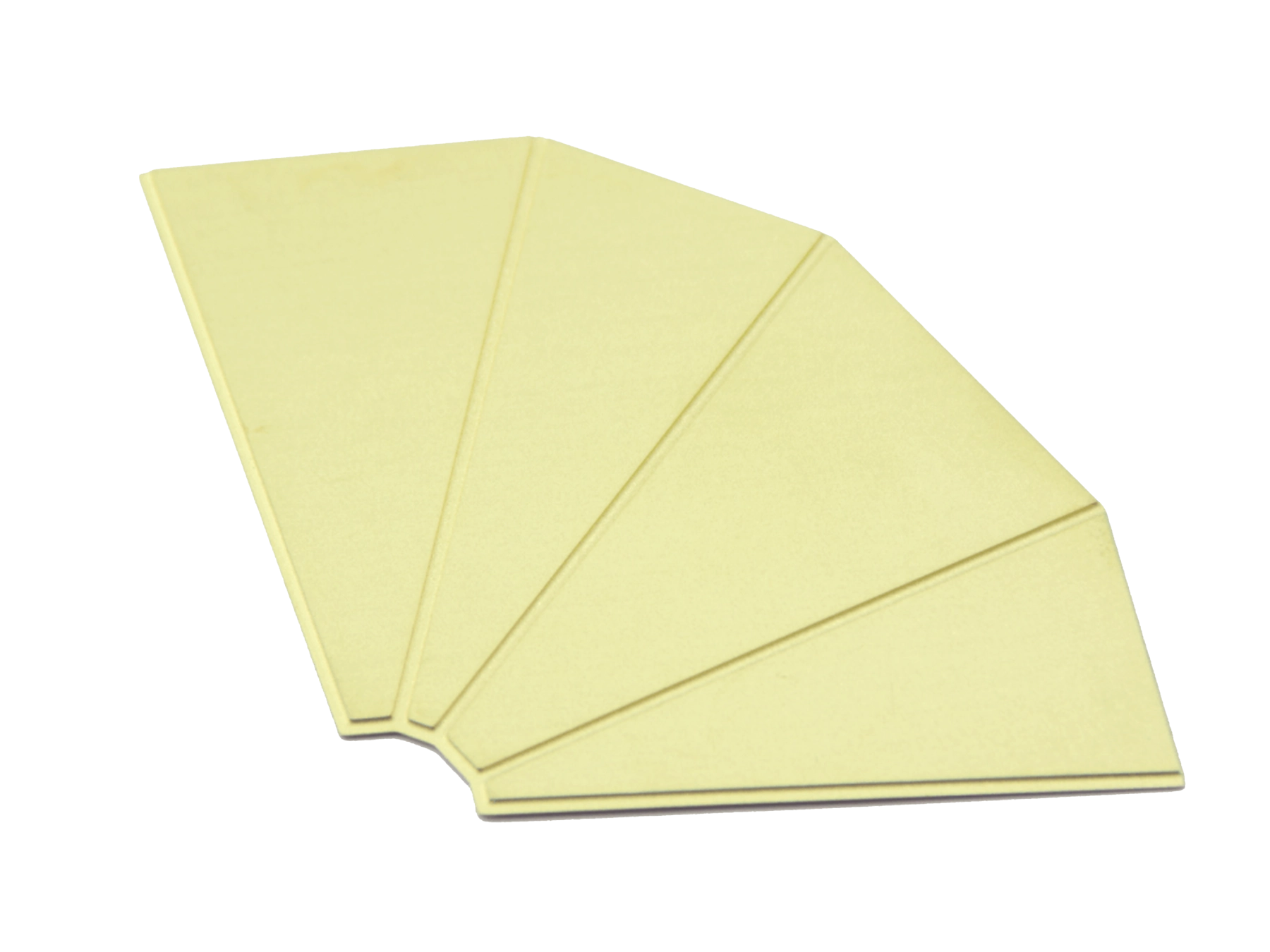

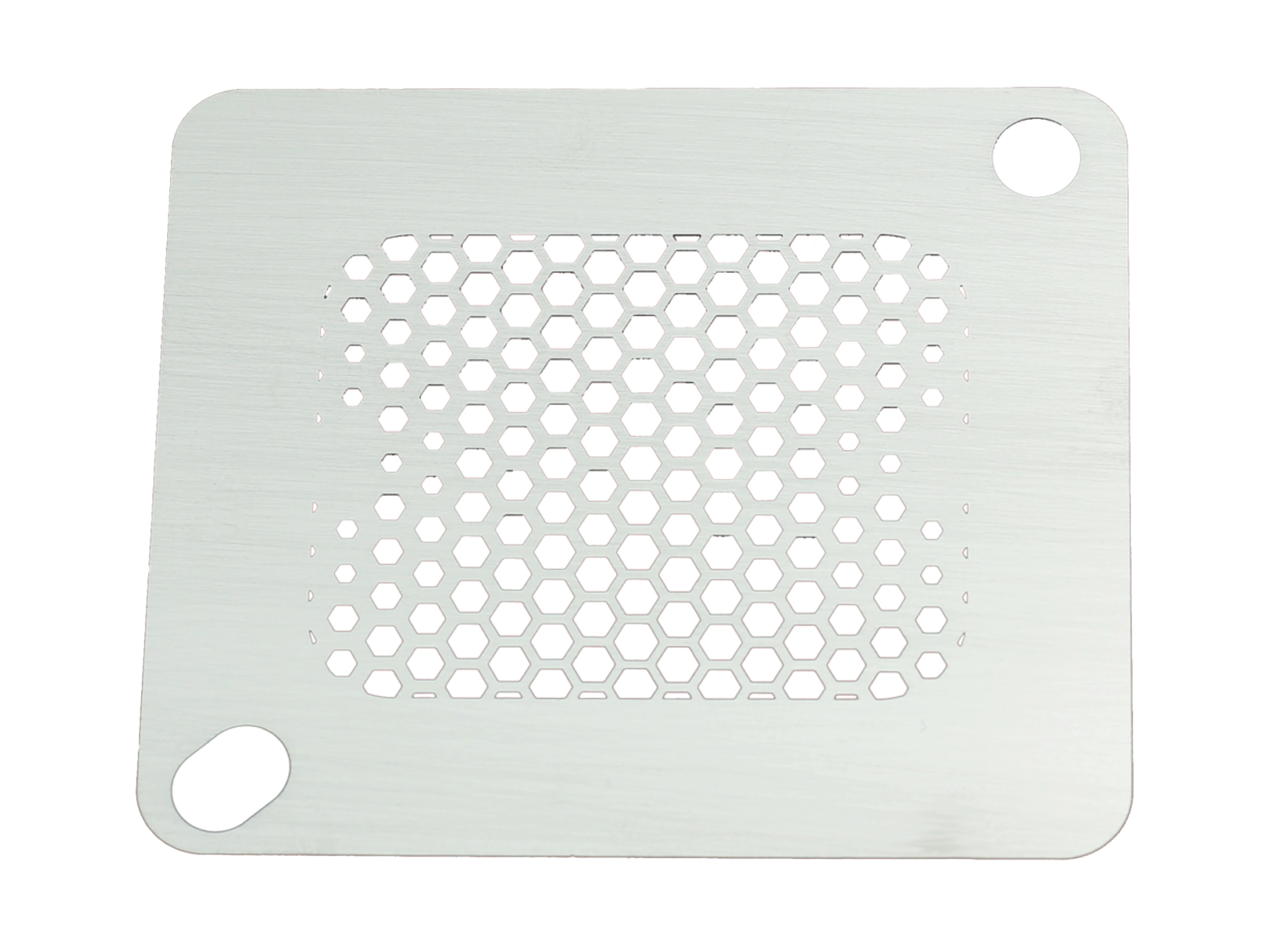

Photochemical etching produces parts with greater complexity and tighter tolerances from thin metals like copper, brass, stainless steel, and more.

Because the photochemical etching process begins on a computer, it is faster to get parts into production, and there are minimal retooling costs or delays if a change is required.

Parts processed via photochemical etching have minimal surface burrs and imperfections, which reduces the need for additional finishing procedures.

We’ve been using photochemical etching since our earliest days, delivering thin metal parts in various materials for the telecommunications, defense, medical, and electronics industries. Here are E-Fab’s photochemical etching capabilities:

| Processes available | Photo etching, chemical blanking |

| Part thickness | ≤ 0.063 thickness |

| Materials worked | Copper, Beryllium Copper, Brass, Phosphor Bronze, Nickel, Nickel Silver, Nickel Iron, Steel, Stainless Steel, Spring Steels, Aluminum, Kovar, and other common and exotic materials |

| Secondary services | Bonding, Plating, Forming, Singulation, De-Tabbing, Blackening, Creating Vias, Through Hole Plating, Anodizing, Clean Room Packaging, Coating, Electropolishing, Passivation |

| Typical turnaround | 3-4 weeks, expedited shipping upon customer request |

| Industries served | Aerospace, Military, Defense, Energy, Fuel Cells, Medical, Microwave, Semiconductor, Telecommunications, Colleges, Secondary Schools, Federal Agencies, State Government, Agriculture, Automotive/Transportation/Mobility, Electronics, Instrumentation & Control Systems, Manufacturing, Technology |

| Typical products | Baluns, Screens, Needles, Circuits, Blades, Solder masks, Labels, Clamps, Standoffs, Battery Switches, Diaphragms, Plates, Boxes, Flow Cell, Springs, Grids, Ion Funnels, Shadow Masks, Circuit Boards, Leadframes, Baffles, Combs, Shields, Heatsinks, Stencils, Electrodes, Clips, Sensors, Lenses, Funnels, Ion Accelerators, Couplers, Ribs, PCBs, Flexes, Flanges, Contacts, Gaskets, BusBars, Microstrip Contacts, Transistors, Covers, Collimators, Terminals, Heat Spreaders, Retainers, Bars, Pins, Actuators, Filters, Brackets, Carriers, Apertures, Frames, Pole Pieces, Encoders, Shims, Cathodes, Stiffeners, Probes, Masks, Microstrips, Spacers, Battery Tabs, Straps, Discs, Lids, Polarizers, Rings, Washers, Antennas |

E-Fab is a proud member of The Partner Companies group of specialty manufacturers. Our network shares experience, materials, capabilities, and expertise to serve the defense, aerospace, medical, telecommunications, semiconductor, and renewable energy industries.

If you need a capability that we do not offer at E-Fab, please let us know, and we will connect you with a TPC company that can help.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us