Precision metal components for the Medical industry

Boasting unparalleled expertise and capabilities in the field, E-Fab consistently produces precise, reliable parts for use in high-tech critical applications for the medical industry.

Leaders in photochemical etching, prototyping, and the production of intricate parts critical for medical applications, we’re the trusted team for an industry that demands meticulous attention to detail throughout the manufacturing process.

Working with innovation and collaboration at our core, we ensure the highest precision, reliability, and safety standards for every medical component we deliver.

Precision

Metal Etching for the Medical Sector

Boasting more than 40 years of experience, the team at E-Fab specializes in delivering precision metal components tailored to the unique needs of our medical clients.

Our proven ability to provide customized, high-precision components tailored to the industry’s unique requirements sets us apart.

Blending experience, expertise, and experimentation, our team of engineers, manufacturers, and quality assurance specialists produce a wide variety of precision metal products that are durable, reliable, and accurate. ISO 9001, we ensure all our components adhere to stringent quality control and compliance standards for medical devices.

Our Medical Capabilities

E-Fab has become a trusted partner for medical clients by providing specialized services and precision metal components that are essential for various medical applications.

In a field where precision is paramount, E-Fab can produce precise fabrication of custom metal components with intricate designs and tight tolerances, perfect for use in various medical devices and equipment.

Our precise metal components designed specifically for medical applications include, but are not limited to:

- Medical sensor elements

- Customized medical device parts

- High-precision screens and filters for sterile medical environments

- Intricate components for medical equipment

- Precision components for medical sensors

- Miniaturized parts for medical device technology

- Medical instrumentation components

The E-Fab Difference

Biocompatibility: We can tailor our photochemical etching processes to work with biocompatible materials such as titanium, stainless steel, and other medical-grade alloys, ensuring the components are safe for use within the human body.

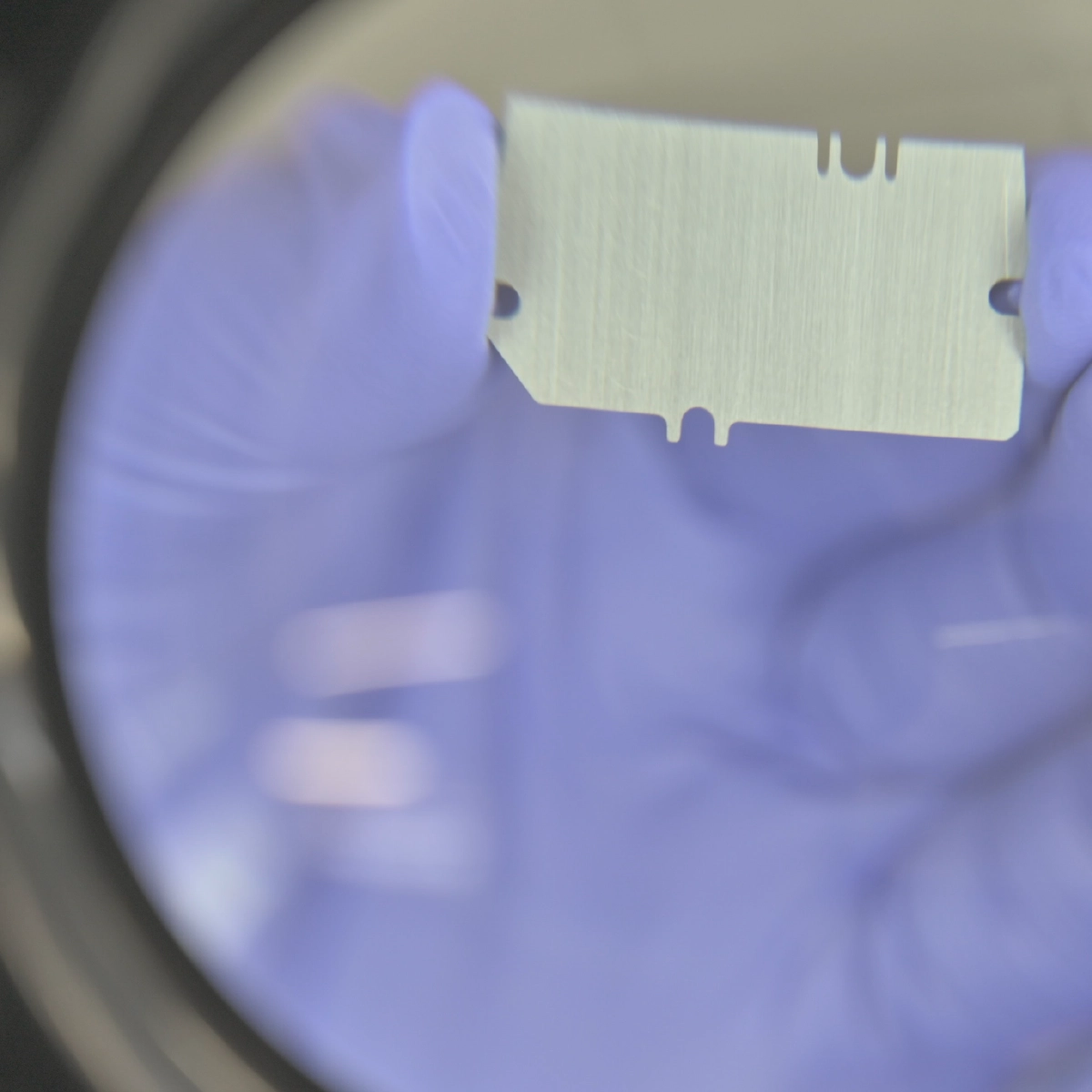

High-Quality Surfaces: Our advanced photochemical etching process delivers high-quality, burr-free, and smooth surfaces crucial for components like stents, catheters, and surgical instruments.

Complex Geometries: Our advanced photochemical etching techniques allow for the creation of intricate and complex two-dimensional shapes, critical for components in medical equipment and implants designed to fit specific anatomical structures.

Microfabrication: We can produce microscale and miniature components, which are increasingly important in minimally invasive surgical procedures, microfluidics, and lab-on-a-chip technologies.

Rapid Prototyping: Our rapid prototyping capabilities are essential for developing and testing new medical devices and components before they enter mass production.

Cost-Effective Production: We help medical manufacturers achieve cost efficiencies through the cost-effective medium to high-volume production of precision components.

Quality Control: Our team of Quality Assurance professionals analyzes every part we send out to ensure each meets technical specifications and precise requirements.

Custom

Component Manufacturing Transforming the Medical Industry

Blending innovation and collaboration, E-Fab is transforming the future of medical technology by providing customized, high-precision components that can be relied on for even the most extreme applications.

Focusing on performance and patient safety, we produce components essential for the proper functioning of medical devices, such as sensors, electrodes, filters, and intricate parts for devices like pacemakers, medical implants, and diagnostic equipment.

We work closely with medical clients throughout the project lifecycle and continually invest in state-of-the-art technology, including direct imaging printers, to ensure accuracy and precision in everything we do.

Boasting unrivaled experience working with a wide range of materials, including exotic alloys and materials with specific properties required in medical applications, we provide durable and reliable components that can perform in the most challenging environments.

Contact Our Medical Component Experts Today

As specialists in precision components for a wide range of medical applications, the team at E-Fab can deliver the highest quality and reliability for your next project.

In a field where precision is paramount, E-Fab is the team you can rely on. Talk to us today.