Phosphor bronze is known for its high strength, low coefficient of friction, and fatigue resistance. Engineers also know the metal for its fine grain, elasticity, and versatility. Our manufacturing experts can form, mold, draw, and punch phosphor bronze.

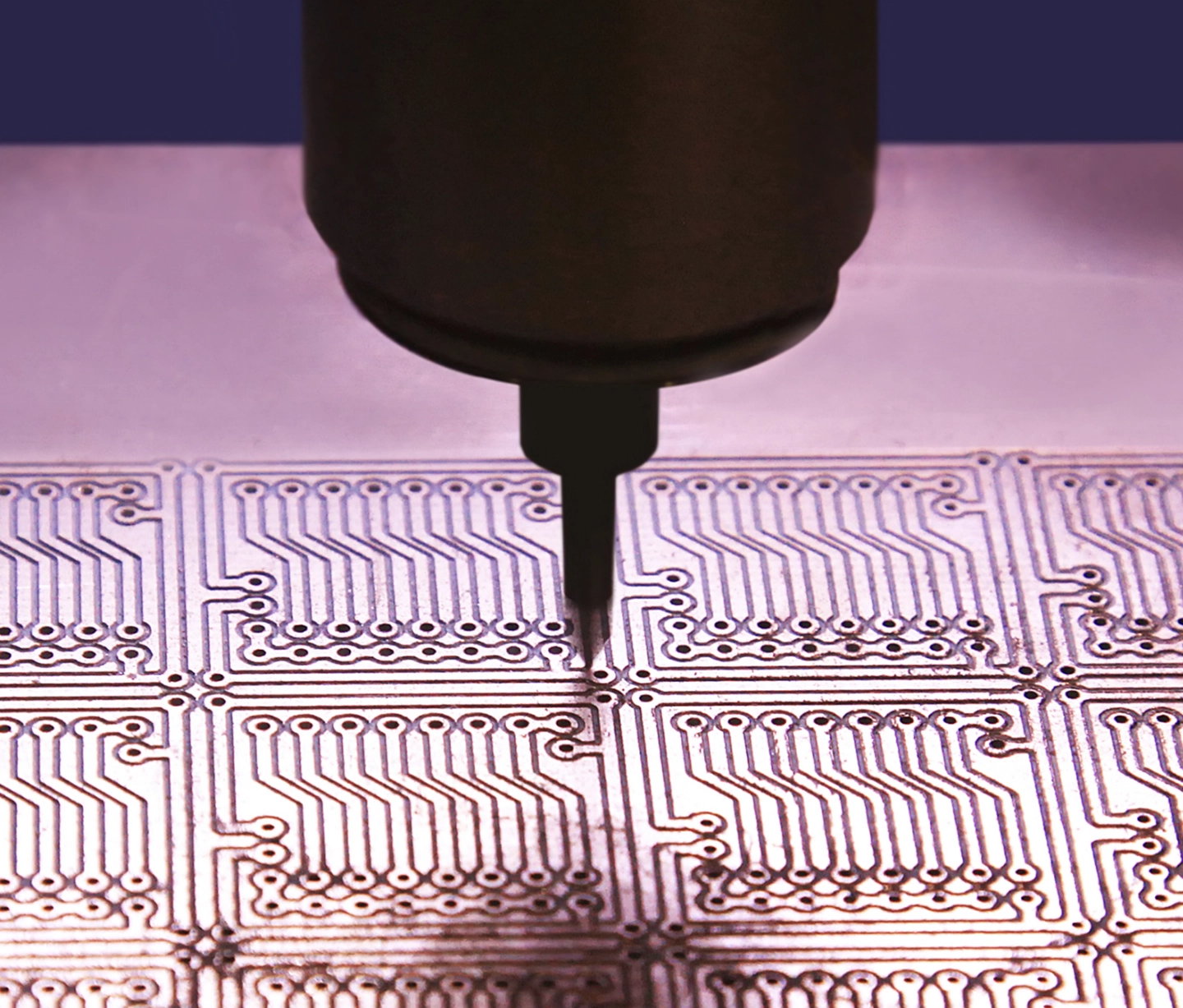

E-Fab’s phosphor bronze manufacturing experience includes producing springs, contacts, clips, magnetic shields, covers, carriers, and contacts for our clients in the electronics industry.

We welcome your questions about how to use phosphor bronze for your parts.