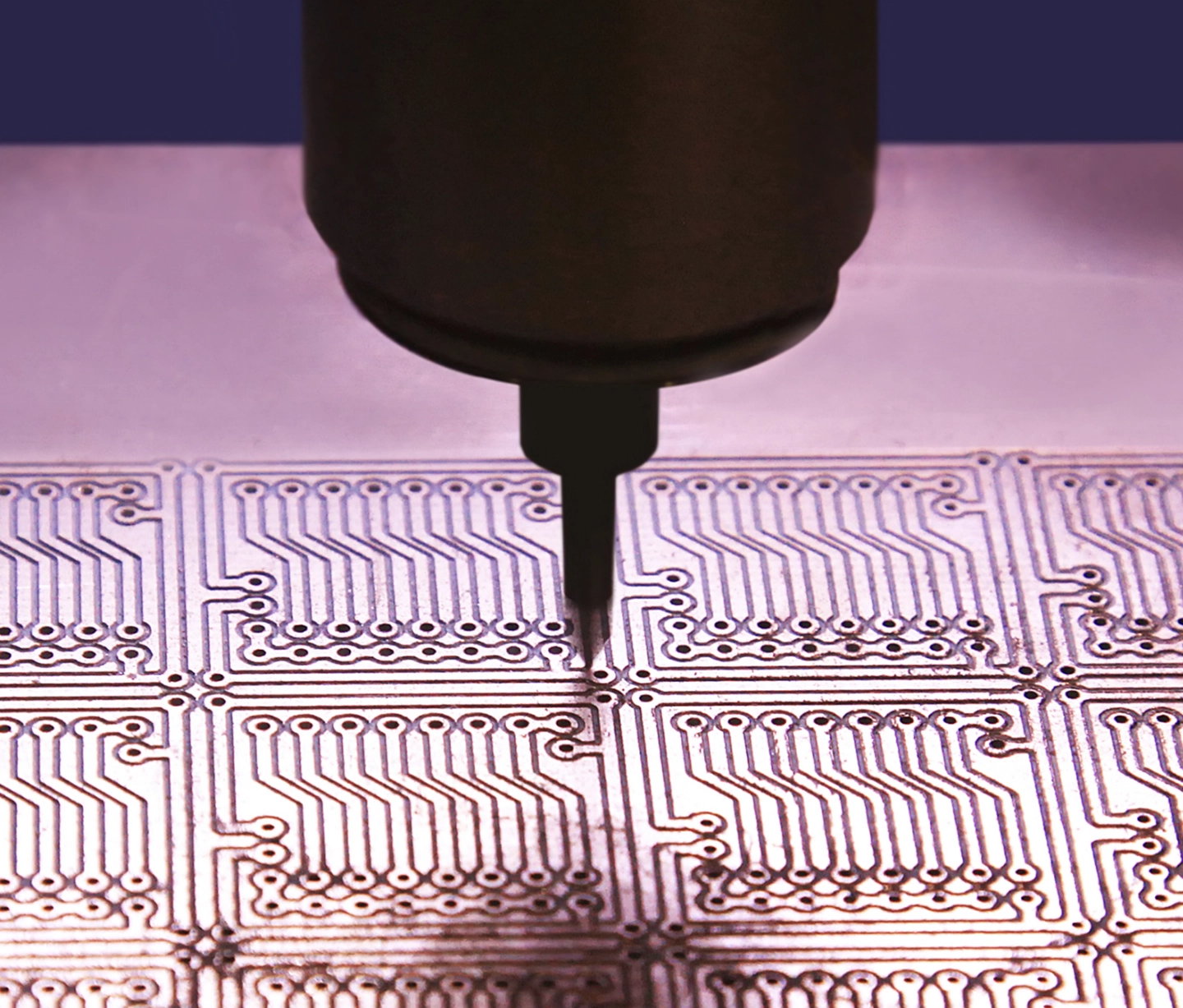

Monel is more challenging to CNC machine than steel because it work-hardens quickly, and its alloys are stronger than pure nickel and are extremely resistant to many corrosive agents, including saltwater and toxic gasses. These properties combined with Monel’s ductility make it an ideal candidate for etching electronic components for oil & gas, marine, and aerospace environments.

E-Fab harnesses these qualities to produce components that perform optimally even under extreme temperature variations and electromagnetic environments.

We welcome your questions about how to use Monel for your parts.