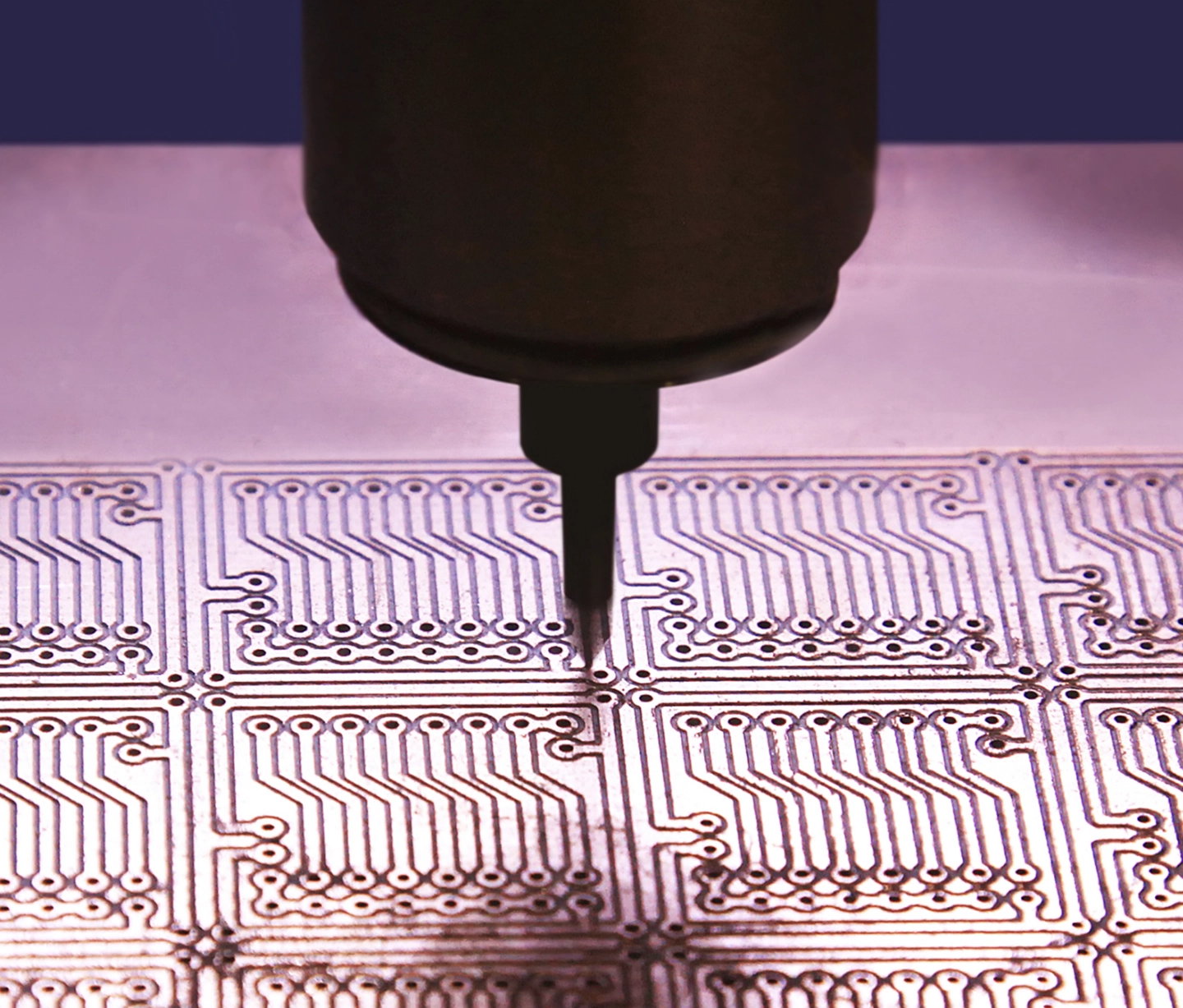

Beryllium copper is the metal of choice when it’s vital to maximize electrical properties, memory, and strength with non-magnetic and low-sparking characteristics. We leverage these qualities when manufacturing microstrip contacts, contacts, and springs.

E-Fab’s engineers and manufacturers have years of experience with the material and understand how to process Beryllium copper safely.

We supply parts made from Beryllium copper to companies working in the telecommunications, electronics, semiconductor, and microwave industries.

We welcome your questions about how to use Beryllium copper for your parts.