Explore the versatile applications of copper bus bars across various industries and how they contribute to the efficiency, reliability, and innovation of modern technologies.

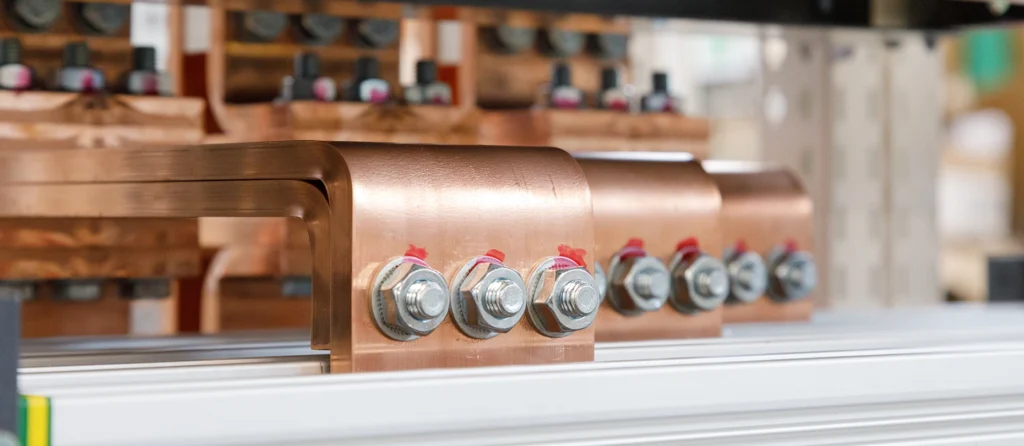

Copper bus bars are unsung heroes of electrical connectivity, powering, and optimizing operations across a wide range of leading industries. This is due mainly to their incredible versatility, which makes them perfect for demanding applications in even the harshest conditions.

From aerospace and defense to technology, semiconductors, and medical, critical electrical systems rely on these essential components to ensure the seamless transmission of power and data.

With decades of experience in the field, E-Fab has established itself as a leading copper bus bar manufacturer and trusted provider of custom metal components. Renowned for consistently delivering reliable, high-quality copper busbars for a wide range of critical applications, E-Fab offers precision manufacturing solutions for industries across the country.

This article breaks down the versatile applications of copper bus bars across various industries and how they contribute to the efficiency, reliability, and innovation of modern technologies.

The Critical Role of a Copper Bus Bar

Composed of high-purity electrolytic tough-pitch copper, copper bus bars are crucial elements in electrical applications due to their outstanding electrical conductivity. These flat, rectangular copper bars efficiently transmit power and signals within electrical systems, minimizing voltage drop and effectively managing heat dissipation. The significance of this humble copper bar lies in its ability to ensure optimal performance and reliability in various applications, from power distribution panels to electronic devices and industrial machinery.

With their exceptional electrical conductivity, copper bus bars are indispensable in powering, connecting, and optimizing electrical systems across diverse industries.

They are essential components for:

Efficient Power Distribution: Bus bars efficiently distribute power to various components, ensuring that electricity reaches its intended destination without loss or degradation.

Space Optimization: Bus bars help optimize space within electrical panels and cabinets by providing a centralized point for electrical connection. This makes installations more compact and organized.

Safety and Reliability: Bus bars contribute to the safety and reliability of electrical systems by minimizing short circuit risks, ensuring stable voltage levels, and facilitating effective heat dissipation.

Powering Critical Systems in Aerospace and Defense

Reliability and performance are paramount in the aerospace and defense sectors. Copper bus bars play a critical role in delivering this by powering and connecting sophisticated avionics systems, radar systems, and communication networks. These high-performance components provide efficient power distribution, withstand extreme environmental conditions, and ensure the uninterrupted operation of vital equipment, contributing to the safety and mission success of aerospace and defense operations.

Efficiently distribute electrical power to various systems and components, the precise, reliable copper bus bars manufactured by E-Fab are used in the following aerospace and defense systems:

Power distribution systems: In aircraft and vehicles, E-Fab’s busbars distribute power from the main electrical supply to different circuits and equipment.

Electrical panels and switchgear: E-Fab’s busbars serve as the main distribution points for power within electrical panels, switchgear, and control systems.

Transportation systems: Our busbars are used in electric trains, trams, and other electric vehicles to distribute power to different parts of the vehicle.

Military equipment: In military systems and equipment, such as communications, power generation, and weapons systems, E-Fab’s busbars are used to distribute electrical power efficiently.

Delivering High-Speed Data Transmission for Technology and Semiconductors

In the fast-paced world of technology and semiconductors, where miniaturization and high-speed data transmission are key, copper bus bars are essential components in a wide range of critical applications.

Their superior conductivity, low resistance, and thermal stability make them ideal for efficiently distributing power and managing heat dissipation in high-performance computing systems, ensuring optimal performance and reliability.

Some of the key applications that rely on E-Fabs copper busbars include:

Industrial electronics: Efficiently distributing high currents while dissipating heat in industrial equipment like motor drives, power inverters, and solar inverters.

Electric vehicles: Connecting the battery packs, power electronics, and electric motors in the power distribution systems of electric vehicles.

Renewable energy systems: Managing the high currents and voltages involved in wind turbines, solar farms, and battery energy storage systems.

Data centers: Connecting servers, cooling systems, and other high-power equipment in the power distribution infrastructure of data centers.

Electrical substations and switchgear: Connecting high-voltage equipment in electrical substations and switchgear.

Circuit boards: Optimizing space and electrical performance of circuit boards by integrating conductive bus bars directly into the circuit board design.

Enhancing the Quality of Medical Care

In a field where precision and reliability can be the difference between life and death, copper bus bars play a crucial role in powering medical imaging equipment and diagnostic and life-saving medical devices.

Copper’s high electrical and thermal conductivity, as well as its malleability and durability, make it a preferred material for medical device power distribution systems that require reliable, high-current carrying capacity. Copper bus bars allow for compact, flexible, and customizable power delivery solutions in space-constrained medical environments.

From MRI machines to pacemakers, these essential components provide the high-quality power supply necessary for large amounts of electrical equipment, accurate diagnostics, and therapeutic interventions, contributing to better patient outcomes and enhanced healthcare delivery.

Some key applications include:

- Electrical switchgear and panel boards in hospitals to distribute power efficiently

- Flexible copper bus bars that provide power connections between distribution bus bars and upstream devices in electrical panels

- Laminated copper bus bars used in power conversion modules of medical equipment

At E-Fab, we focus on performance and safety, producing copper bus bars essential for the proper functioning of medical devices, such as sensors, electrodes, filters, and intricate parts for devices like pacemakers, medical implants, and diagnostic equipment.

Custom Copper Bus Bars to Optimize Your Electrical Systems

Does your company need a proven partner for quality copper busbar production? The team at E-Fab is here to help. Experts in photochemical etching, our precise copper components play a pivotal role in powering, connecting, and optimizing operations across various industries.

Cost-conscious and customer-focused, our knowledgeable team assists customers with every step of the project, from consultation to design to manufacturing to delivery, and provides high-quality product solutions that precisely satisfy their requirements.

Materials experts and highly experienced working with copper, aluminum and other alloys, our precision photochemical etching process and industry-leading equipment in our ISO 9001:2015 certified facility ensure that every component we fabricate doesn’t just meet but far exceeds the industry standard.

Request a quote today or contact us for more information.