Whether you are in the prototype phase still going through design iterations, or are about to scale up production, E-Fab is ready to deliver high-precision photochemical etching services using our advanced equipment and skilled team of technicians. Our experts partner directly with engineers and buyers across all major sectors, including critical industries dependent upon a reliable U.S. supply chain like aerospace, defense, medical, and semiconductor manufacturing to deliver quality parts on time.

Still in the design phase? Let’s get you connected with one of our experts to kick-off your project today!

Ready to ramp up the volume? Let’s get you a quote today so we can hit the ground running!

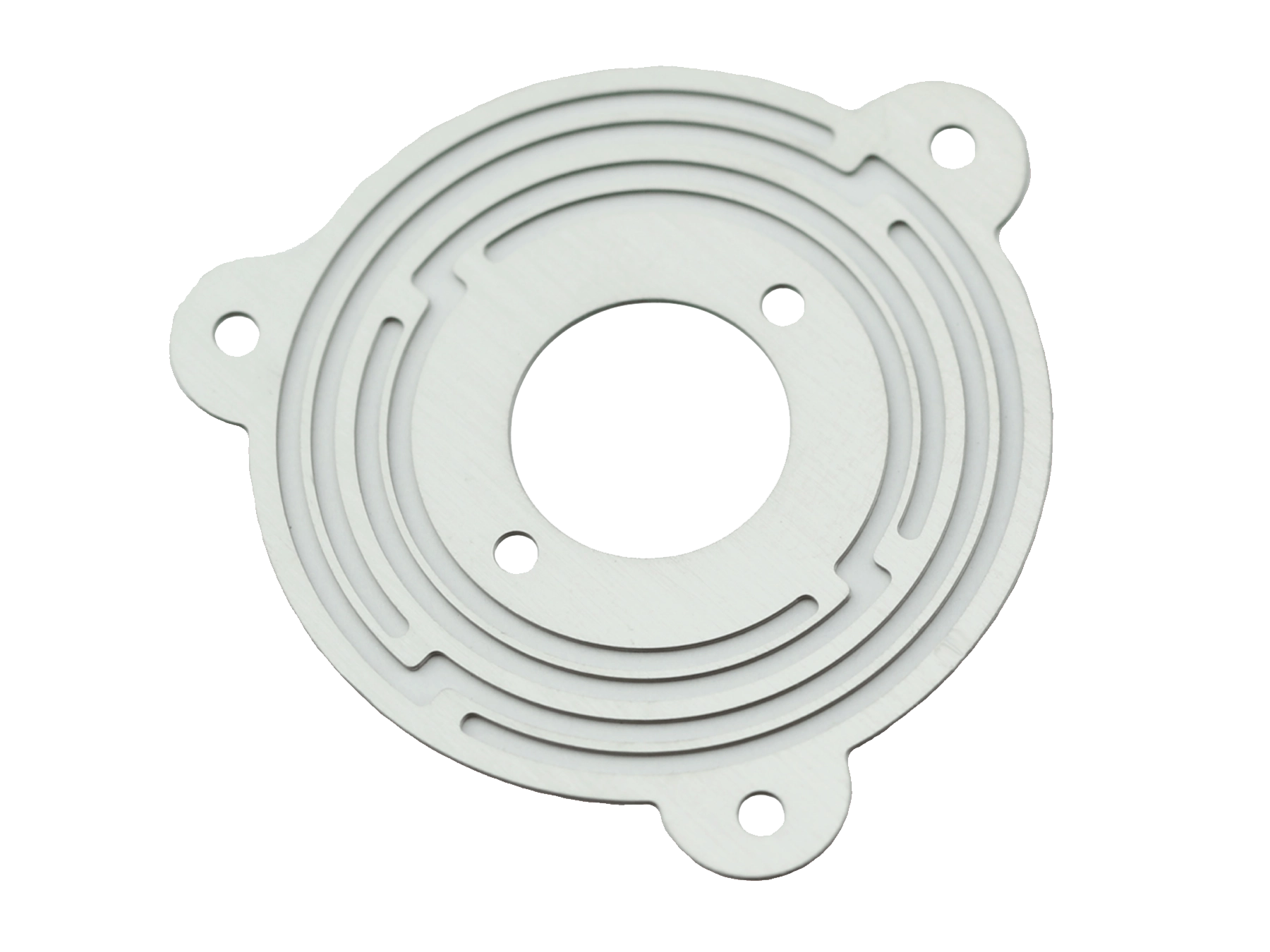

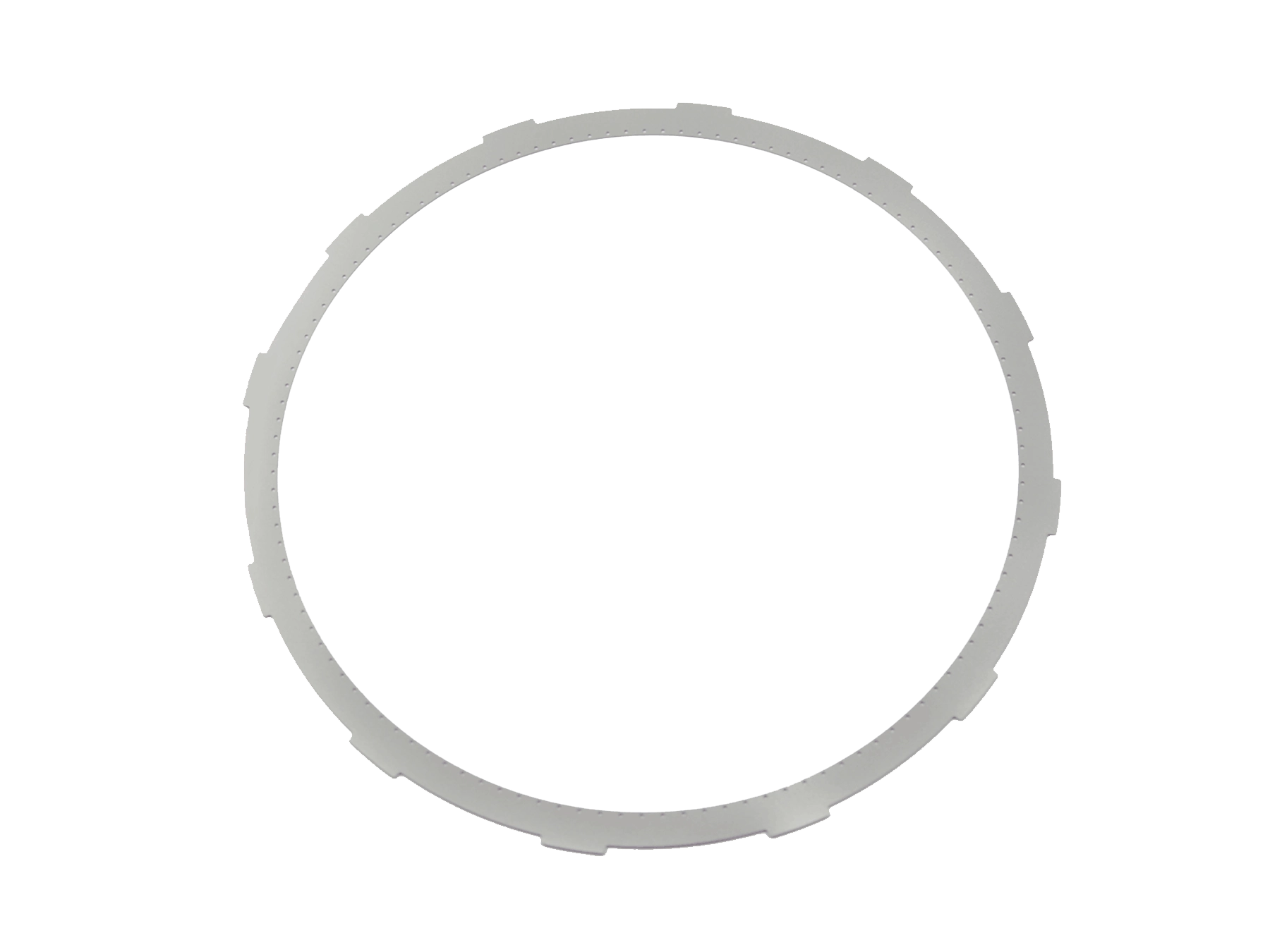

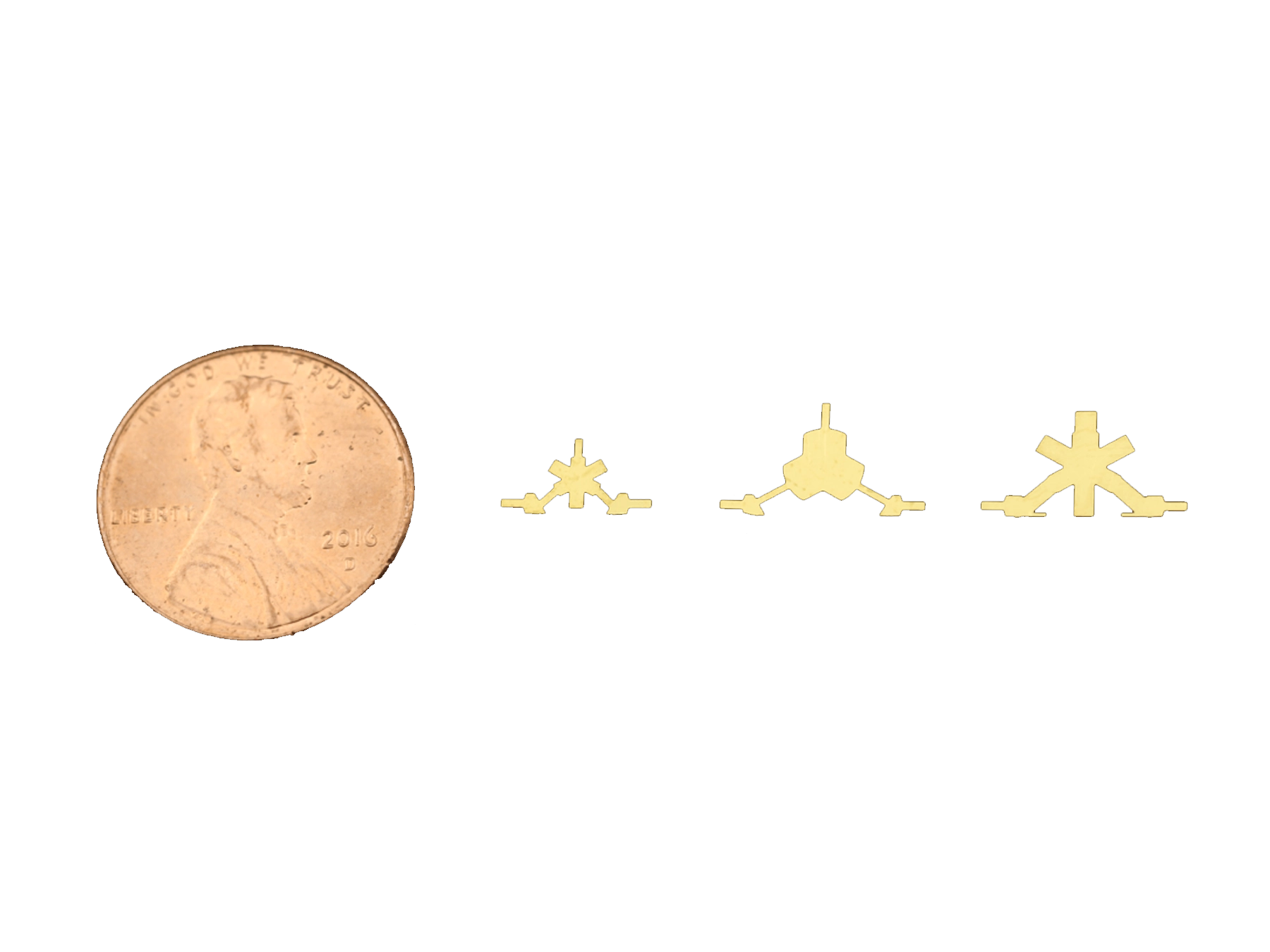

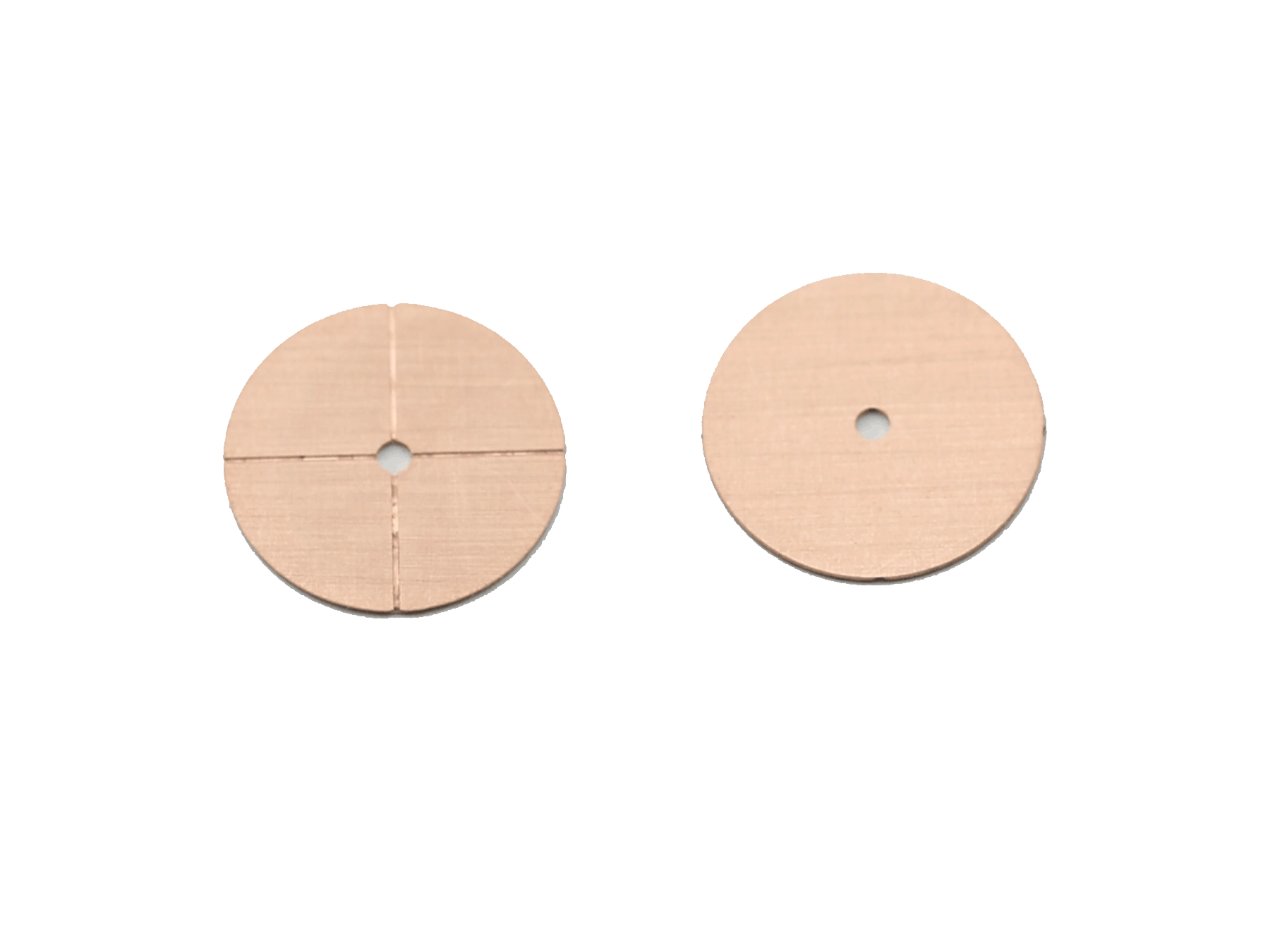

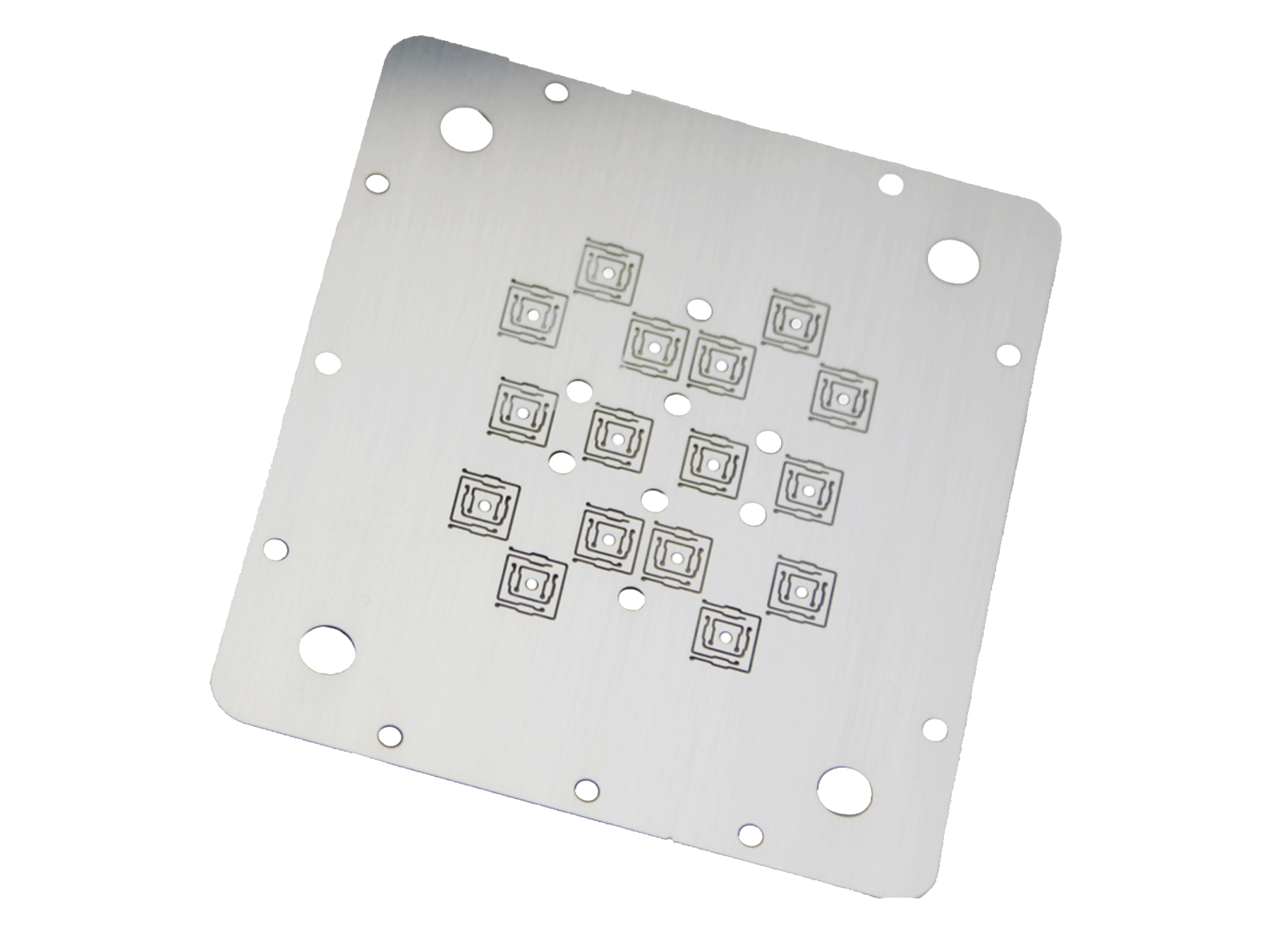

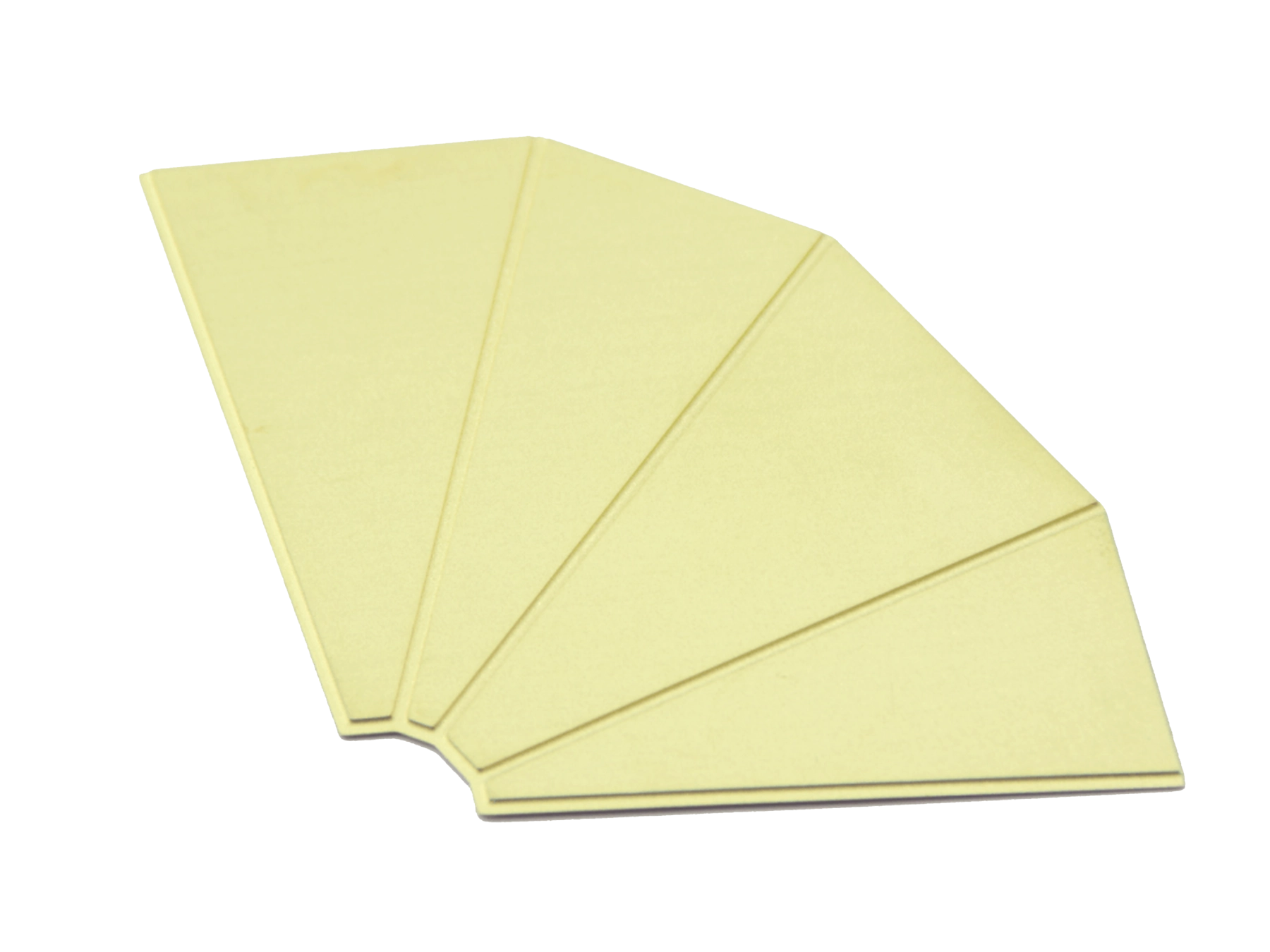

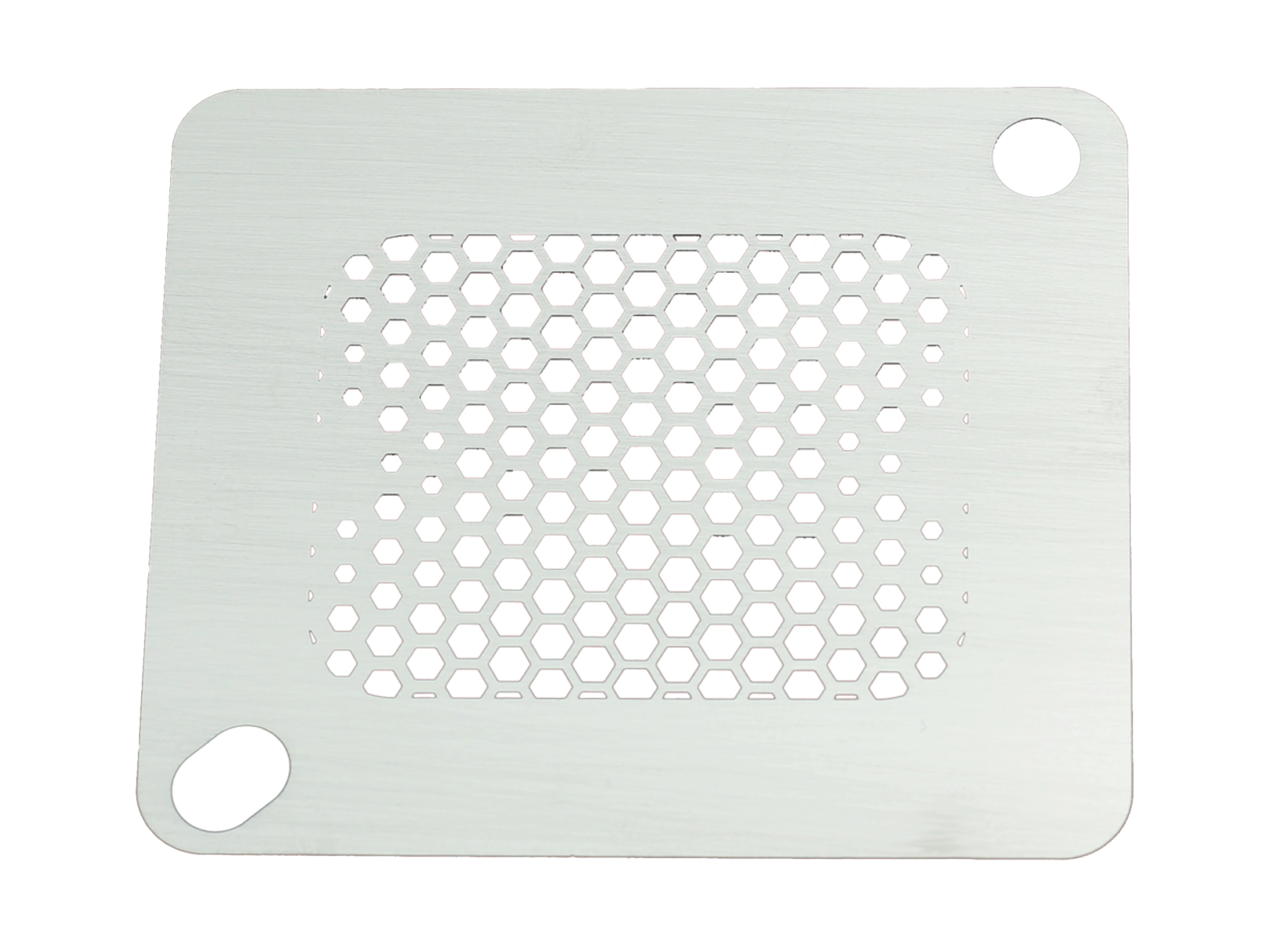

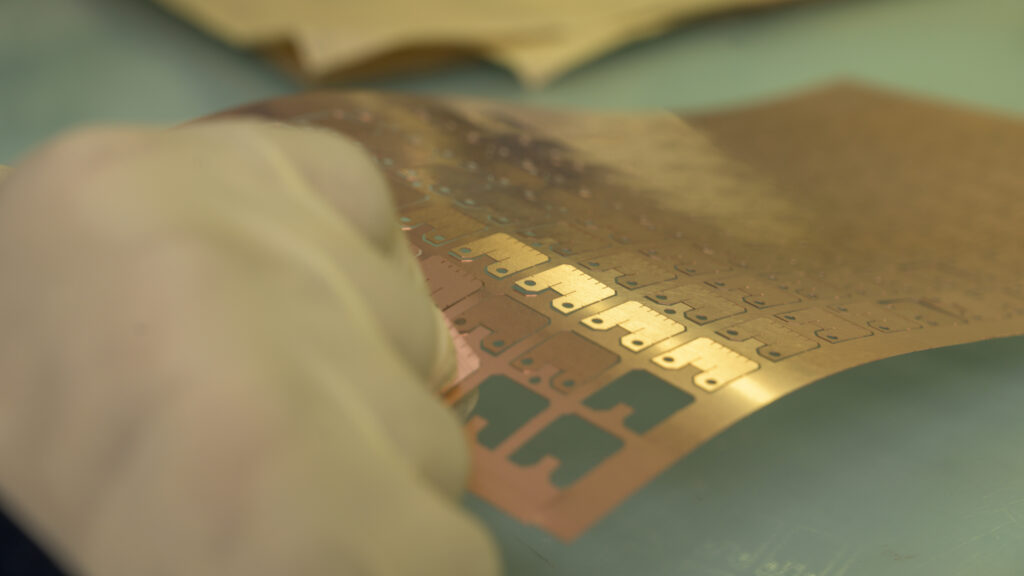

Photochemical machining, also known as photochemical etching or chemical milling, is a subtractive manufacturing process that uses photoresists and etchants to remove unwanted material to produce a highly precise metal component. Ideally, this process is used when working with thin materials that have complex geometry and dense design features, without inducing thermal stress and distortion into the component that typically takes place when using traditional manufacturing methods.

| Material Thickness | 0.0005 in – 0.063 in (0.013 mm – 1.60 mm) |

| Standard Tolerance | ±0.0005 in – ±0.002 in , depending on material thickness and feature size |

| Minimum Feature Size | 120% of material thickness |

| Supported Materials | Stainless Steel, Copper, Tungsten, Titanium, Kovar, Invar, Molybdenum, Various Nickel Alloys and More |

| Volume Flexibility | Prototyping – High-Volume Production |

| Secondary Services | Bonding, Plating, Forming, Finishing, Brazing, Packaging, and More |

| Quality Certifications | AS9100 and ISO9001:2015 Certified, ITAR Registered and RoHS Compliant |

Typically, 2-4 weeks with expedited options available, depending on the project’s complexity and material availability

Absolutely, we offer comprehensive assistance throughout the process. Our engineers are ready to help you solve your challenges.

With over 40 years of photochemical etching expertise, E-Fab delivers precision, consistency, and reliability across every project we contribute to. Our U.S.-based facility as well as other TPC facilities are ISO 9001:2015 certified, ITAR certified, and RoHS compliant, ensuring that we maintain the highest quality standards for all the components we produce.

We offer rapid prototyping, scalable production, and the flexibility to work with a wide range of metals and alloys. From initial design collaboration to final delivery, our responsive engineering team partners closely with our customers to ensure that we support the exact requirements of their objectives.

Whether you are a seasoned veteran who knows exactly what they need, or you could use some additional resources like our Design Guide, E-Fab is ready when you are to produce complex parts through our photochemical machining process, that we’ve spent decades mastering.

We look forward to supporting your mission and the opportunity to work together, Request a Quote today to get the conversation started.

If you need a capability that we do not offer at E-Fab, please let us know, and we will connect you with a TPC company that can help.

With its high precision and efficiency, photochemical etching is quickly becoming the preferred process for industries that require accuracy and quality. Offering a number of