Precision-manufactured components are the foundation of functionality, reliability, and innovation in modern medical technology.

From diagnostic equipment and surgical instruments right through to implantables, these precision parts play a crucial role in a wide range of critical applications, ensuring that modern medical devices operate effectively, safely, and consistently.

Boasting more than 40 years of proven experience and unrivaled expertise, E-Fab leads the way in precision photochemical etching, prototyping, and the production of intricate medical device parts critical for medical applications. Our team of dedicated engineers, manufacturers, and quality assurance specialists work collaboratively with clients to deliver a wide array of custom-engineered medical parts that meet the most demanding specifications.

In this article, we explore the importance of precision in medical devices and the applications of precision parts in medical devices that help deliver advanced medical care.

The Importance of Precision in Medical Devices

As the medical industry continues to advance at a rapid pace, the demand for quality of care and quality of life continues to increase. As a result, a range of new innovative medical devices are making their way to market. However, with the health and safety of patients on the line, the components for each device must be manufactured to the highest levels of quality and precision.

Unlike other industries, medical devices must perform flawlessly under various conditions, often within the human body, where margins for error are minimal. For example, surgical instruments must be finely tuned to perform delicate procedures without causing unnecessary tissue damage. MRI machines and CT scanners on the other hand require highly accurate components to produce clear, reliable images.

As a result of their critical nature, these devices must be made and designed with precision.

The Advantages of Photochemical Etching for Medical Components

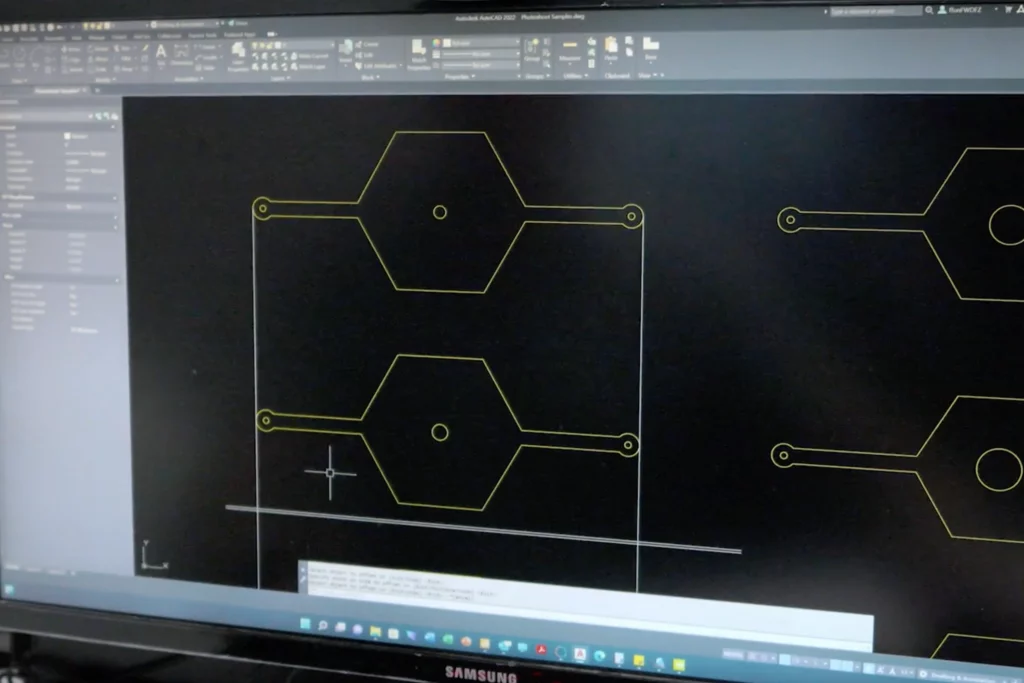

With its ability to provide a level of precision and flexibility that’s hard to achieve with traditional machining methods, photochemical etching has become the popular choice for manufacturing the components required for medical devices.

This innovative process allows for the creation of intricate designs and complex geometries with high accuracy, making it ideal for producing components like surgical instruments, implantable devices, and microfluidic systems. It’s also a non-contact, burr- and stress-free method, which preserves the integrity and biocompatibility of the materials used, ensuring the highest quality and reliability in various critical medical applications.

Applications of Photochemically Etched Parts in Medical Devices

Precision metal parts are relied on for a wide variety of medical devices, providing the accuracy, reliability, and intricate design necessary for advanced medical care.

The key applications include:

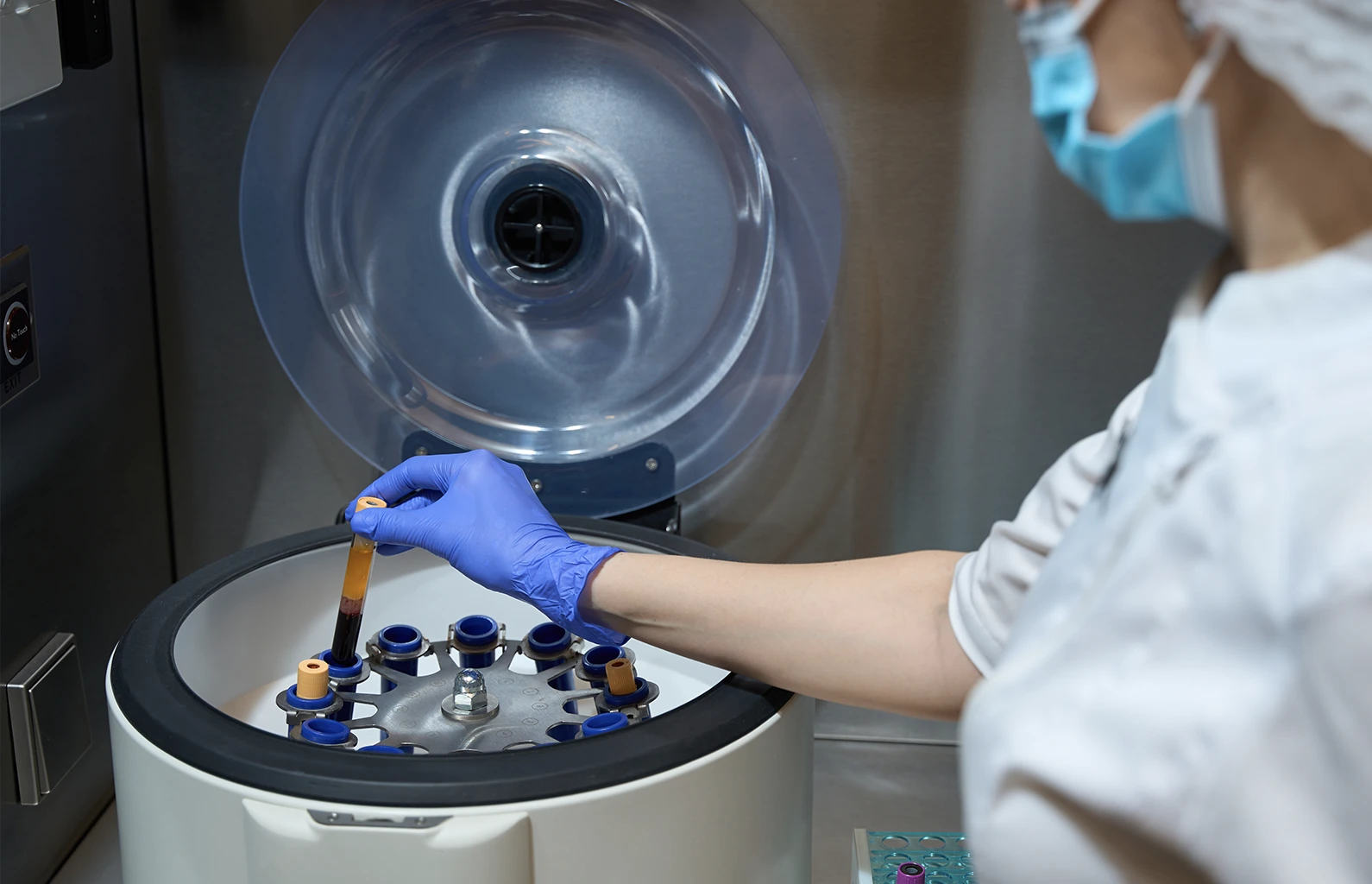

Diagnostic Equipment Components

Photochemically etched components are essential for the reliable performance of MRI machines, CT scanners, and ultrasound devices. The ability to create intricate, highly accurate parts etched components helps to ensure high-resolution imaging that doctors depend on for accurate diagnoses.

Surgical Instruments

Photochemical etching (PCE) is essential in producing fine-cutting tools, scissors, forceps, and minimally invasive surgical instruments. By enabling the creation of sharp, precise edges and intricate designs without burrs, the process ensures that these surgical instruments perform with the highest effectiveness and safety during procedures.

Implantable Devices

Etched components, including those made from biocompatible titanium, play a key role in pacemakers, stents, and orthopedic implants by ensuring the biocompatibility and precision needed for these critical devices. The chemical etching process produces components with smooth surfaces and complex geometries, which are essential for the seamless integration of these implants within the human body. This precision ensures that the devices function reliably over time, supporting patient health and safety.

Medical Filters and Meshes

Precision components are vital in blood filtration devices, surgical meshes, and implants. The photochemical etching process enables the production of fine, consistent apertures and patterns, ensuring these components effectively filter fluids or support tissues within the body.

Hearing Aid Components

Photochemical etching is essential in creating miniature components and intricate circuits for hearing aids. Unlike traditional machining methods, this technique allows for the high precision and miniaturization required to produce compact and efficient designs, which are crucial for the functionality and comfort of hearing aids.

Endoscopic Tools

By enabling the creation of highly detailed and flexible parts for flexible and rigid endoscopic tools, PCE ensures these tools can navigate the body’s internal structures with the precision necessary for successful procedures. The accuracy of the components produced through PCE is paramount to the maneuverability and overall functionality of endoscopic tools, ensuring they perform reliably in complex medical environments.

Respiratory Equipment Components

The precision components in ventilators and other respiratory support devices are crucial for their effective operation. Photochemical etching (PCE) enables the production of highly accurate and reliable parts that meet the stringent demands of respiratory equipment. This precision ensures that these life-saving devices perform flawlessly when needed most, supporting patient health in critical situations.

E-Fab’s Capabilities in Precision Engineering

E-Fab specializes in producing high-precision metal components crucial for the medical industry. Our extensive expertise spans various capabilities, including photochemical machining, high-frequency laminate processing, plating and finishing, bonding, and forming.

With a proven ability to provide customized, high-precision components tailored to the industry’s unique requirements, the team at E-Fab is helping to advance the next generation of medical device manufacturing.

Our precise metal components designed specifically for medical applications include, but are not limited to:

- Medical sensor elements

- Customized medical device parts

- High-precision screens and filters for sterile medical environments

- Intricate components for medical equipment

- Precision components for medical sensors

- Miniaturized parts for medical device technology

- Medical instrumentation components

Quality Assurance and Reliability

In an industry where safety and precision are non-negotiables, you need to work with a manufacturing partner with robust quality control systems in place to detect and correct any deviations in the manufacturing process.

At E-Fab, we take pride in our commitment to excellence and ensuring the highest quality standards throughout our manufacturing processes. To achieve this, we hold compliance certifications (ISO 9001:2015, ITAR, CMRT), ensuring all our components adhere to stringent quality control and compliance standards for medical devices.

Our team of Quality Assurance professionals analyzes every part we send out to ensure each meets technical specifications and precise requirements.

Why Partner with E-Fab for Medical Device Components

With over 40 years of experience, E-Fab is a proven leader in the medical field specializing in the production of intricate and precise metal components for the medical sector.

When you partner with E-Fab you get access to advanced medical machining, rigorous quality control, and customized solutions tailored to the unique needs of this complex and evolving industry.

What sets E-Fab apart:

Biocompatibility: We can tailor our photochemical etching processes to work with biocompatible materials ranging from titanium and stainless steel to other medical-grade alloys, ensuring the components are safe for use within the human body.

Complex Geometries: Our advanced photochemical etching techniques allow for the creation of intricate and complex two-dimensional shapes, critical for components in medical equipment and implants designed to fit specific anatomical structures.

Rapid Prototyping: Our rapid prototyping capabilities are essential for developing and testing new medical devices and components before they enter mass production.

Cost-Effective Production: We help medical manufacturers achieve cost efficiencies through the cost-effective medium to high-volume production of precision components.

Powering the Medical Industry Now and In the Future

Precision components play a pivotal role in the functionality, reliability, and innovation of a wide range of modern medical devices. Whether it’s diagnostic equipment, surgical instruments, or implantable devices, the meticulous design and manufacture of these components are essential for ensuring the best possible outcomes for patients.

As technology and medical devices continue to advance and evolve, the demand for precision-engineered parts will only grow and so will the need for manufacturers who specialize in photochemical etching.

In a field where precision is paramount, E-Fab can produce precise fabrication of custom metal components with intricate designs and tight tolerances, perfect for use in various medical devices and equipment. Offering unparalleled expertise in photochemical etching, cutting-edge technology, and a commitment to delivering the highest quality products, they stand out as a clear leader in precision medical components manufacturing.

By partnering with E-Fab, you ensure that your medical components are manufactured to the highest standards, enhancing the efficacy and safety of your medical devices.

If you need a proven manufacturing partner for your medical components, discover E-Fab’s experience and expertise in producing the next generation of medical technologies.