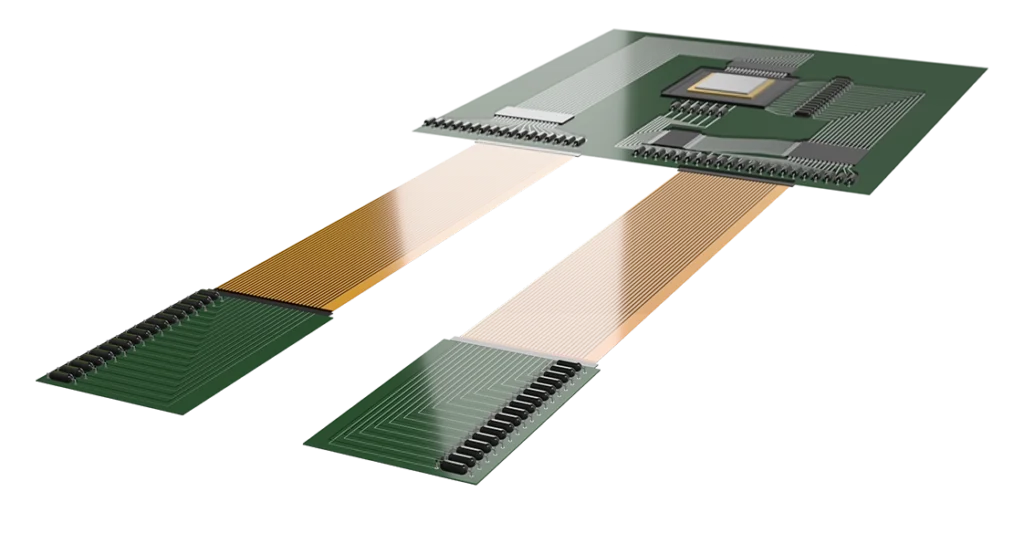

Precision Flex Circuits, also known as flexible circuits, are a slimmer, space-saving replacement for bulky wires or cables. Made using metal that is insulated with material like polyimide, the main function of a flex circuit is to connect electronic devices together, which can translate into any industry or application. These flex circuits can bend, twist, and even fold, and because of the insulation, the circuits can withstand higher temperatures, be more resistant to contamination, and even reduce EMI noise.

With years of experience working with custom designs most suppliers shy away from, E-Fab continues to build our capabilities and knowledge. We have the manufacturing abilities to etch thicker metals and a vast range of alloys using our photochemical etching process. Our capabilities include the raw manufacturing of the actual flex circuits, which allows us to build precision flex circuits, sculptured flex circuits, custom etched flex circuits, and hybrid circuit packages.

Through both our quality assurance and decades of experience, E-Fab combines that with the latest manufacturing technology and fabrication techniques to produce some of the most complex engineering designs with critical requirements. We not only provide physical hardware, but we also specialize in service to support circuit board manufacturers around the nation. Recognizing our unique position in the market, our team truly can do what no other flex circuit shops can.

E-Fab builds these components for most of the critical industries in the world, which have strict quality requirements. To meet those engineering and performance requirements, we can customize and manufacture flex circuits from the following materials:

Excellent for electrical and thermal conductivity, a critical component to any robust design.

Lightweight, durable, and cost-effective, with thermal properties that provide additional benefits to performance.

Used as stiffeners to provide mechanical support for applications that require additional strength.

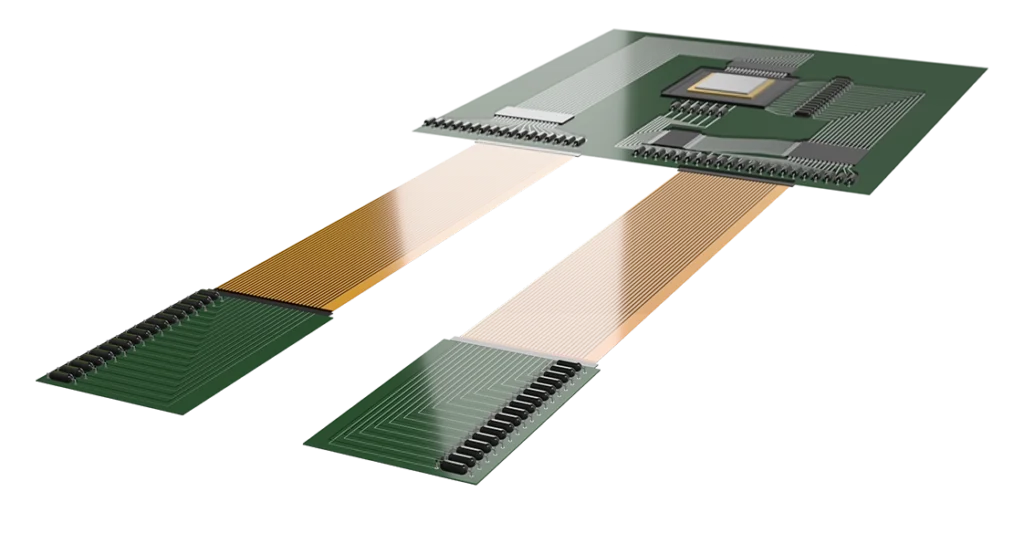

Flexible circuits are used in a wide range of applications and practically every single industry. For years E-Fab has made custom flex circuits to be used in mission-critical applications such as flight control and navigation systems in the aerospace and defense industries. The following are some of the industries that utilize our various flex circuits:

Aerospace: Satellite communication systems, radar components, avionics, and spacecraft systems.

Medical Devices: High-powered scanning equipment, LED lighting, wearable and implant devices, diagnostic and patient monitoring systems.

Automotive: Power controllers and regulating devices, infotainment systems, and sensors, cameras and advanced driver-assistance systems.

Telecommunication: Radio and cellphone towers, headsets, smartphones, tablets and laptops.

We understand the importance of precision and reliability and take pride in knowing that we provide both without compromise. Through our combined experience and stringent quality requirements, E-Fab’s team ensures that your project stays consistent from start to finish.

With the ability to think outside the box and tackle the tougher designs, E-Fab continues to be a trusted partner to our clients and a leading Flex Circuit supplier. Contact us today to request a quote for your project.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us