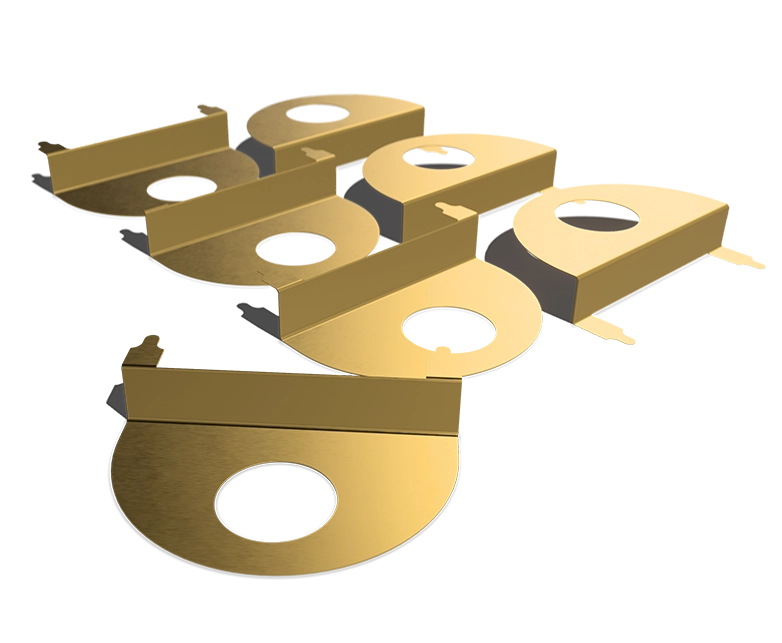

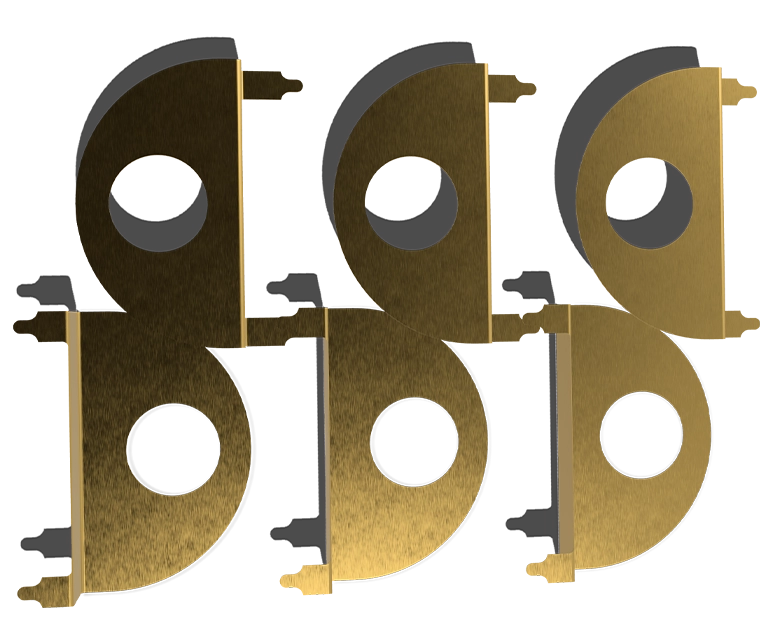

Contacts are critical components in electrical and electronic applications, ensuring reliable conductivity, durability, and precision in high-performance circuits. E-Fab leverages photochemical etching to produce high-precision, burr-free contacts with intricate designs, fine tolerances, and material versatility. This process enables customization, high-volume production, and cost efficiency, making E-Fab’s contacts manufacturing the ideal solution for semiconductors, automotive, medical, and industrial applications.

The dependability of a functioning system often traces back to the electrical components of the design. Everything can be built to perfection, but if even the simplest electrical signals are not correctly sent and received, the whole operation comes to a screeching halt or, worst case, catastrophic failure occurs due to the adverse effects of the missed electrical connection.

E-Fab understands that certain projects bring a particular level of concern with high-stakes applications; we recognize how imperative it is that all electrical contacts work consistently and reliably, without exception. Fortunately, we’ve been able to hone our skills and master our craft when manufacturing electrical contacts through decades of experience, which we carry into each and every new project we approach, saving our clients time and headaches.

Photochemical etching enables ultra-fine features, intricate designs, and exact tolerances. Supports complex geometries, multi-layer designs, and selective plating options. Eliminates burrs and mechanical stress common in stamping and machining processes.

No expensive hard tooling is required, allowing for rapid prototyping and high-volume production. Reduces waste and enables efficient manufacturing of thin, high-density contact designs.

Designed to withstand high temperatures, environmental exposure, and mechanical wear. Plating options (gold, silver, palladium) enhance longevity and conductivity.

Through research and development across several industries, E-Fab has accumulated a plethora of knowledge over time that positions us as a premier supplier for complex contacts that are subjected to rigorous conditions. In tandem with our quality assurance, E-Fab’s experienced team confidently produces reliable connectivity with high accuracy and unmatched performance. We use the latest equipment, technology, and years of hands-on experience to provide our clients with the right materials that produce optimal performance.

High conductivity, commonly used for power and signal transfer.

Excellent spring properties, wear resistance, and thermal stability.

Corrosion-resistant and ideal for high-reliability applications.

High strength-to-weight ratio and biocompatibility, suitable for medical device applications.

Electrical contacts play a vital role in integrated circuits (ICs), chip carriers, and connectors for high-performance electronics. You can pull any major electronic device off the shelf, like a laptop, cell phone, or tablet, and you will find electrical contacts throughout the entire device. The same can be said about satellites, cars, medical equipment, and the entire power sector as a whole. As technology continues to get smaller, while conversely demanding higher performance and longevity, precision electrical contacts are becoming increasingly crucial to the difference between success and failure.

Automotive & EV Technology: Essential for battery terminals, sensors, and electronic control units (ECUs) in modern vehicles.

Medical Devices & Healthcare Technology: Enables precise electrical connections in implantable devices, diagnostic equipment, and wearable technology.

We have the resources and capabilities to take on the most challenging projects. Our engineering team fiercely ensures all parts and services meet your specifications and perform as expected.

Our experience and ability to think imaginatively, continue to maintain E-Fab as a trusted partner to our customers and premier Electrical Contacts supplier. Reach out to us today to request a quote for your project.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us