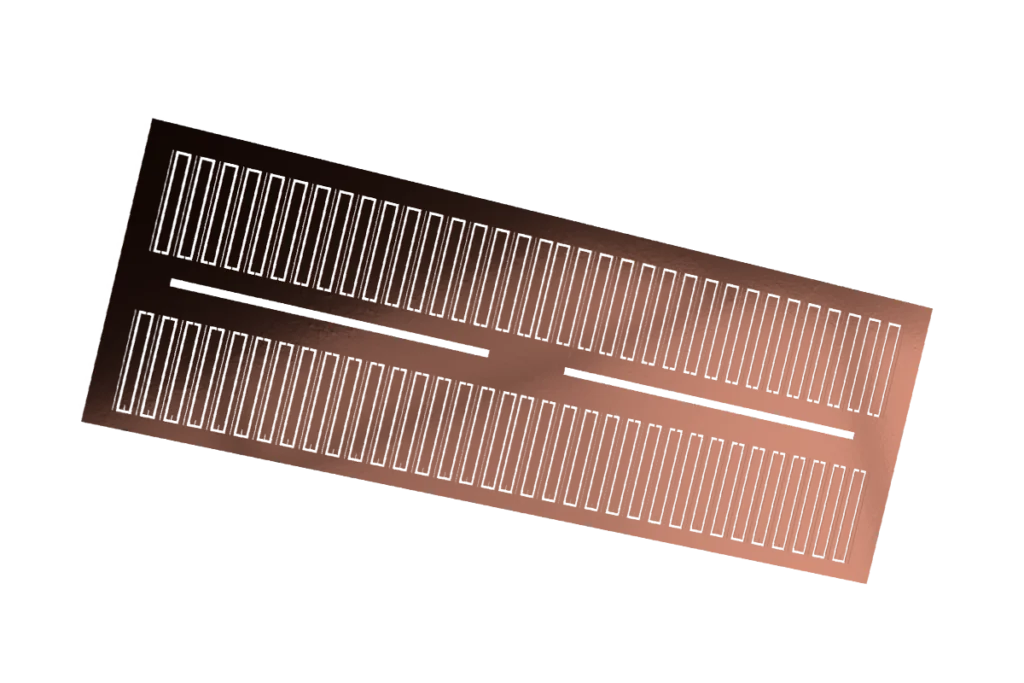

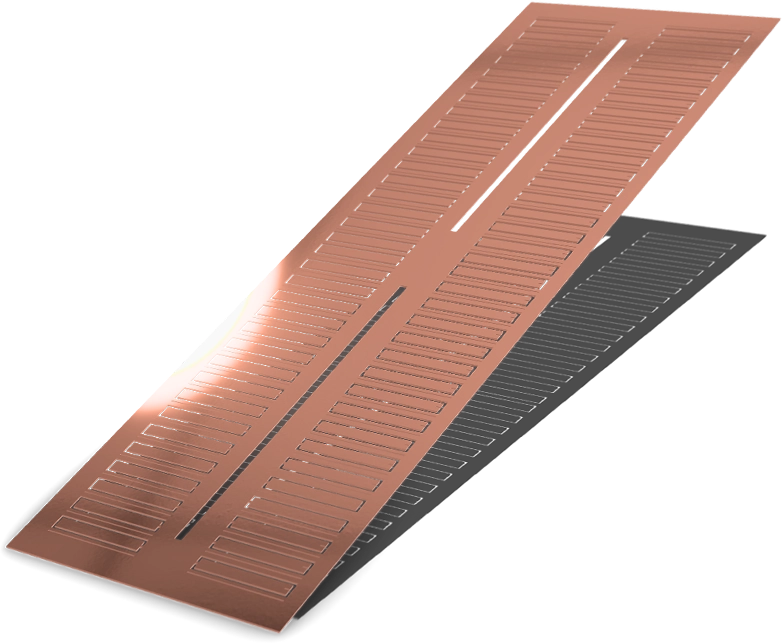

Lead frames are critical components in semiconductor packaging, providing the necessary electrical connection between the silicon chip and the external device. Using the photochemical etching process, E-Fab delivers high-precision, highly customizable lead frames with intricate geometries, fine features, and exceptional consistency. The photochemical etching process ensures high performance, cost efficiency, and material versatility, meeting the stringent demands of modern electronics and semiconductor industries.

Lead frame manufacturing usually involves using copper or other alloys as the base material. Engineers often ask to plate lead frames for additional corrosion resistance and increased performance.

E-Fab offers a full range of additional value-added services, such as forming, plating, and bonding, to ensure your designs function as anticipated and provide exceptional and reliable performance.

E-Fab has been perfecting our skills in this field for decades, incorporating new technology and mastering our fabrication techniques to provide high-quality lead frames for our clients and their projects. From rapid prototyping to full-scale production, we’ve learned throughout the years the importance of integrating precision lead frames throughout a design, of which we’ve highlighted those critical aspects to consider.

Lead frames bridge semiconductor chips and the external circuit, ensuring reliable electrical performance. Maintaining precise alignment and conductivity for optimal signal transmission and reduced resistance.

Our cost-effective method of photochemical etching eliminates the need for hard tooling, reducing upfront costs and lead time, which quickly transition to rapid prototyping and high-volume production. Enabling intricate, fine-pitch designs without burrs, mechanical stress, or heat distortion, unlike stamping or laser cutting.

Supporting complex geometries without sacrificing quality, ultra-thin cross-sections, and micro-scale features for high-density circuits. Components can be tailored to specific applications with multiple plating options, selective etching, and multi-layer capabilities.

It’s essential for lead frames to withstand extreme temperatures and mechanical stresses to support high-performance semiconductor devices in industries where durability is critical.

Choosing the proper materials is critical in the performance and functionality of lead frames. Whether it be thermal stability, conductivity, corrosion resistance, or a balanced combination, picking the correct material is crucial, especially for critical applications.

High conductivity and excellent thermal dissipation, commonly used in microelectronics.

Corrosion-resistant with good solderability, ideal for long-term reliability.

Low thermal expansion, perfect for applications requiring dimensional stability.

High-strength and durable for specialized industrial and high-wear applications

Lightweight and durable, perfect for aerospace and automotive needs.

E-Fab’s research and development experience spans several industries, giving our engineers a wealth of knowledge that positions us as a premier supplier of complex designs of thin metal parts used in extreme conditions.

Our manufacturing experience and focus on quality assurance give our customers the confidence that they’ll receive lead frames with high accuracy and unmatched performance that produce reliable connectivity.

The following industries use E-Fab’s photochemically etched lead frames:

Semiconductors & Microelectronics: Essential for integrated circuits (ICs), microprocessors, and transistors in consumer electronics and computing.

Automotive Electronics: Used in ECUs, sensors, and control modules for advanced automotive applications, including ADAS and EV technology.

We have the resources and capabilities to take on challenging projects. Our engineering team vigorously ensures all parts and services meet your specifications and perform as expected.

Our experience and ability to think creatively have made E-Fab a trusted partner to our customers and a premier Lead Frame supplier. Contact us today to request a quote for your project.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

1009 Timothy Drive

San Jose, CA 95133

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us