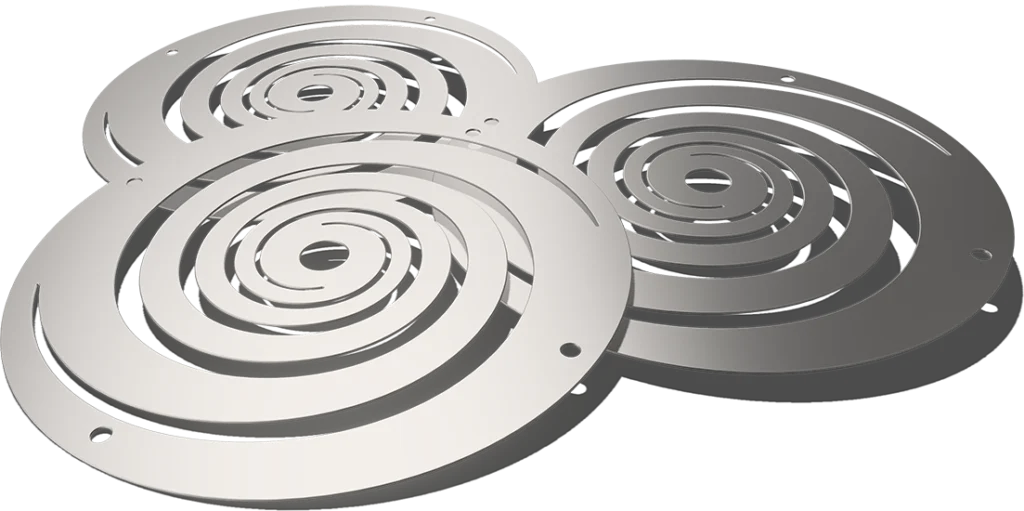

E-Fab’s photochemically etched (PCE) springs deliver unparalleled precision and reliability for critical applications across multiple industries. By combining photochemical etching with advanced materials, E-Fab produces springs with intricate geometries, tight tolerances, and consistent performance. These springs are engineered to meet demanding requirements in industries such as aerospace, medical, electronics, and energy.

E-Fab brings decades of experience working in photochemical etching, with both standard metals like stainless and titanium, as well as more exotic alloys that include copper, bronze, and nickel. When choosing a partner to produce your PCE springs, you can trust us to apply our industry experience and understanding of materials to produce the highest functioning springs on the market. We leverage our extensive experience gained over the years to ensure your project avoids the headaches and hardships during the design phase that so many engineers endured previously.

Precision springs are critical components that can play a decisive role in whether or not a system will be successful. Even more so are photochemically etched springs, given the high-stakes applications that typically require them, often referred to as “ultra-precision” due to the extremely tight-tolerance requirements and structural integrity demanded. PCE springs allow engineers to ensure critical connections are maintained in adverse conditions that would otherwise fail when using outdated spring technologies or manufacturing methods.

Achieve extremely tight tolerances and consistent performance in high-stress environments.

Photochemical etching allows for intricate spring designs without the limitations of traditional manufacturing.

Create springs from a variety of materials to suit diverse applications and environments.

Photochemical etching eliminates the need for costly tooling, making it a cost-effective solution for custom designs.

Easily scale production from prototypes to high volumes without sacrificing quality.

Depending upon the application, like so many designs, the material selection is a critical aspect of functionality. Luckily for our clients, E-Fab has experience working with all of them, and our team can lend assistance where needed to ensure your designs are using the optimal materials based on the application requirements.

Some of the most common applications include:

Excellent for electrical conductivity, durability, and fatigue resistance in electronics.

Known for elasticity and resistance to corrosion, suitable for precision mechanical systems.

Lightweight and strong, with excellent fatigue and corrosion resistance for aerospace and medical use.

Exceptional heat and corrosion resistance for springs used in extreme environments.

A multitude of industries require precision spring components to ensure reliable and repeatable functionality, these range from automotive applications to hold components in place during operation, as well as medical applications like pacemakers to ensure they don’t miss a beat. We’ve worked in these varying industries which has allowed our team to learn from each experience uniquely. This has positioned E-Fab as a best-in-class spring providing for some of the most widely used, and demanding sectors of the world, and beyond.

Aerospace: Provide reliable tension, compression, and alignment in critical flight components.

Medical Devices: Ensure precise performance in surgical tools, implantable devices, and diagnostic equipment.

Electronics: Deliver consistent electrical connections and functionality in circuit boards, connectors, and microelectronics.

Energy: Support renewable energy systems, such as solar panels and wind turbines, with durable, high-performance springs.

Automotive: Enhance performance in engines, suspensions, and transmission systems.

Industrial Equipment: Ensure durability and flexibility in machinery and assembly lines.

We have the resources and capabilities to take on challenging projects. Our engineering team vigorously pursues excellence for both the parts and our services, ensuring your specifications and performance expectations are achieved, without compromise.

Our experience and ability to think creatively, have made E-Fab a premier partner to our customers and leading PCE springs supplier. Contact us today to request a quote for your project.