Why Tungsten: How Tungsten Plays a Crucial Role

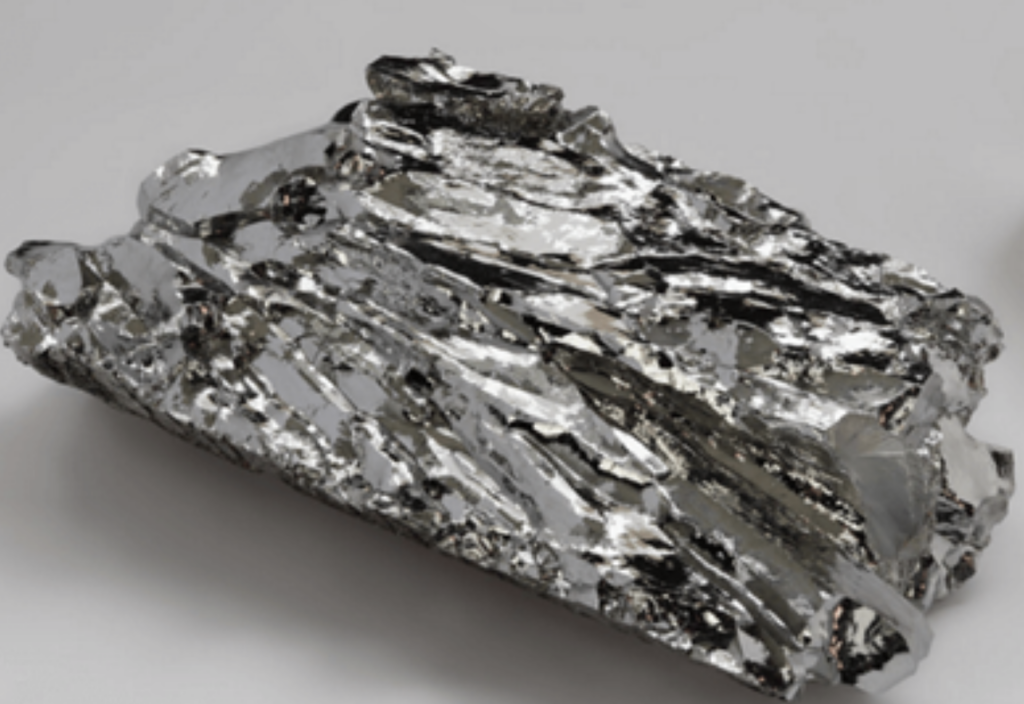

Tungsten is a refractory metal known for its exceptional properties, including the highest melting point of any metal (3422°C / 6191°F), superior strength, and high density. Tungsten also offers increased corrosion resistance, making it highly durable in harsh environments, withstanding exposure to corrosive substances better than many other metals. Tungsten also retains its impressive hardness when alloyed, making it a versatile and reliable choice for various industries and specialized applications. These characteristics make it an extremely useful candidate for intricately etched parts and components.

Challenges of Tungsten-Specific Applications

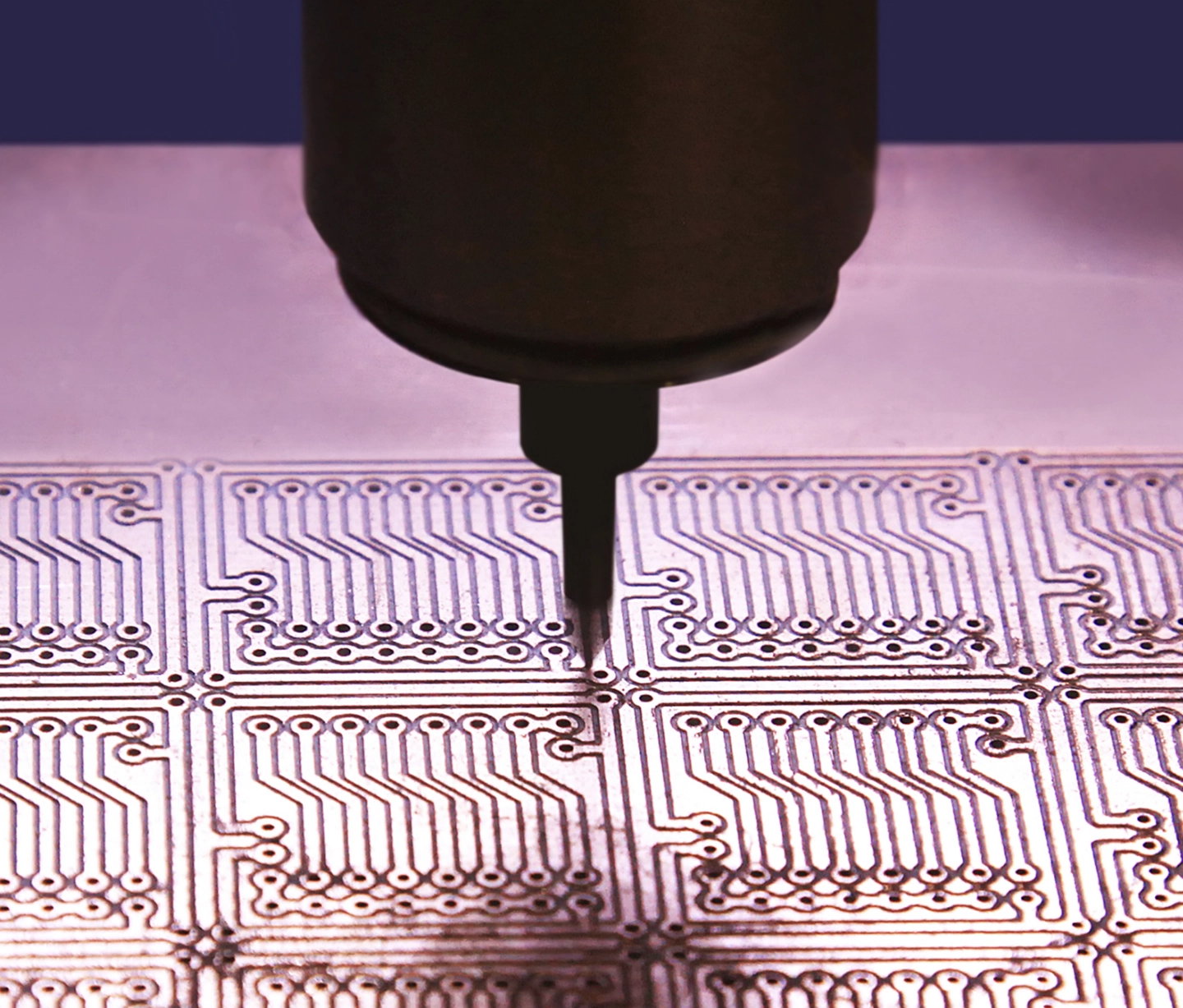

The tungsten etching process involves a chemical solution known as tungsten etchant, a mixture of mildly alkaline potassium ferricyanide and potassium hydroxide, which selectively dissolves the unprotected areas of the tungsten sheet, resulting in the desired pattern.

The biggest challenge of working with tungsten is the material integrity itself, as it can be brittle or result in substantial warping, especially for thin metal parts. So, traditional manufacturing processes like CNC machining, EDM, or even the latest additive manufacturing techniques aren’t enough when it comes to the level of intricacy required for most electronic applications that continue to get smaller while still requiring the same if not more, performance. Our photochemical etching process eliminates this stress and distortion, which is critical when producing extremely intricate, small parts that are increasingly integrated into the medical and semiconductor industries.

We’ve developed a specific manufacturing process to mitigate these issues using photochemical etching (PCE) to create complex parts. We continue to provide custom solutions for our customers while ensuring the material integrity and longevity perform consistently throughout the life cycle of the application. This process results in a burr-free, straight edge and smooth finish that maintains tight tolerances while also being a cost-effective option in comparison to traditional machining methods.

E-Fab Continually Provides Solutions for Tungsten PCE

Photochemically etched tungsten is a versatile and indispensable material relied on by some of the world’s leading industries. Its unique properties, combined with the precision and intricacy of the etching process, have seen it quickly become a preferred material in various high-performance applications.

At E-Fab, we leverage our extensive knowledge of the etching process and our deep understanding of the molecular behavior of tungsten to ensure that we are producing the highest quality parts at every level. This is supported by our proven ability to hold tolerances below 70 µm on large arrays (up to 300 x 600 mm).

We also provide a full range of services that bring value to your tungsten application, including forming and plating that produce enhanced properties specific to your project, making E-Fab a preferred partner within many supply chains.

From This

To This