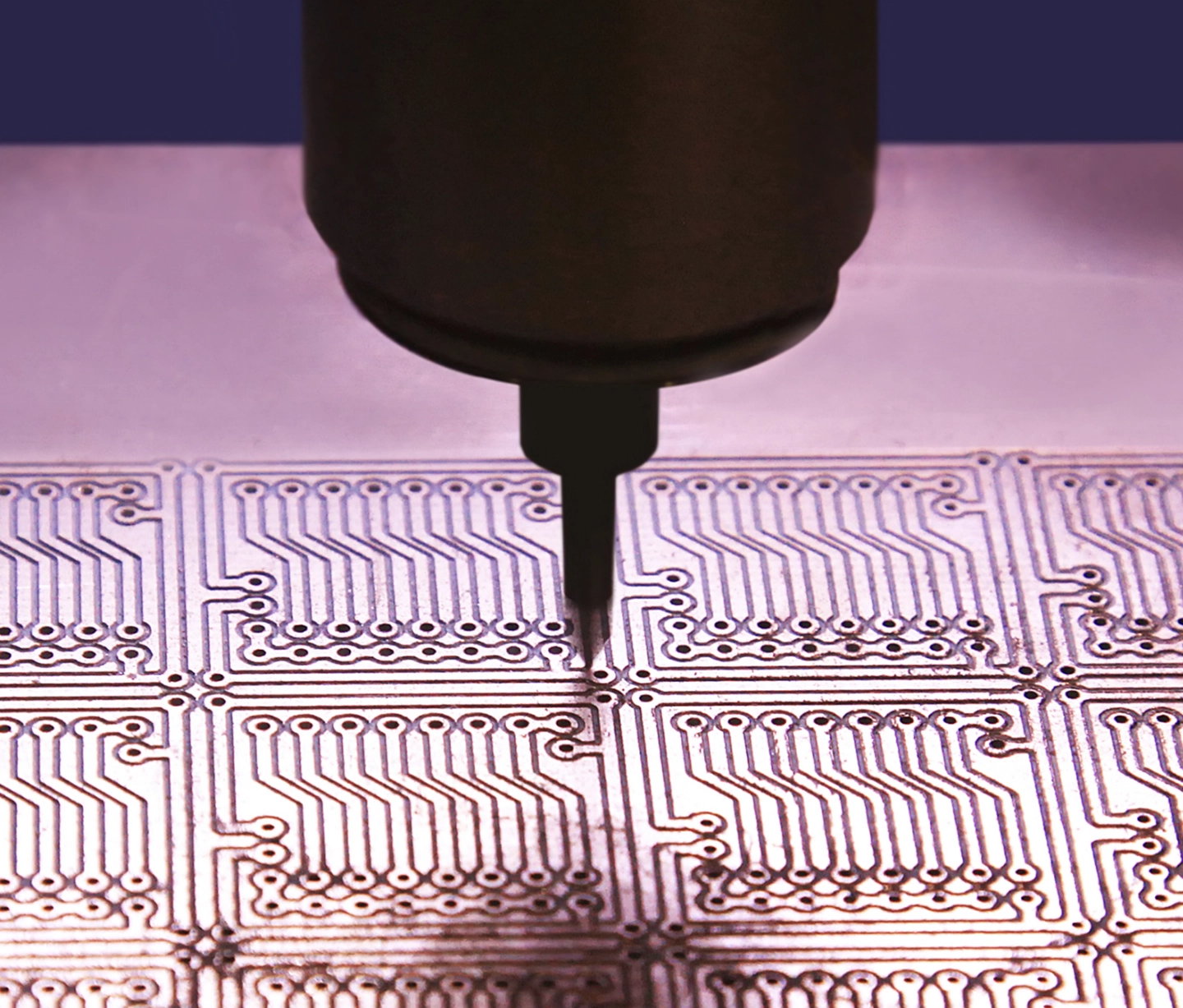

E-Fab specializes in the photochemical etching of titanium, delivering critical parts for industries such as aerospace, medical, defense, and renewable energy.

Titanium earns its reputation as a substantial metal due to its exceptional blend of properties. It boasts a remarkable strength-to-weight ratio, making it indispensable for aerospace and defense components. Its lightness enhances fuel efficiency and maneuverability, while its strength supports higher payload capacity.

We welcome your questions about how to use Titanium for your parts.