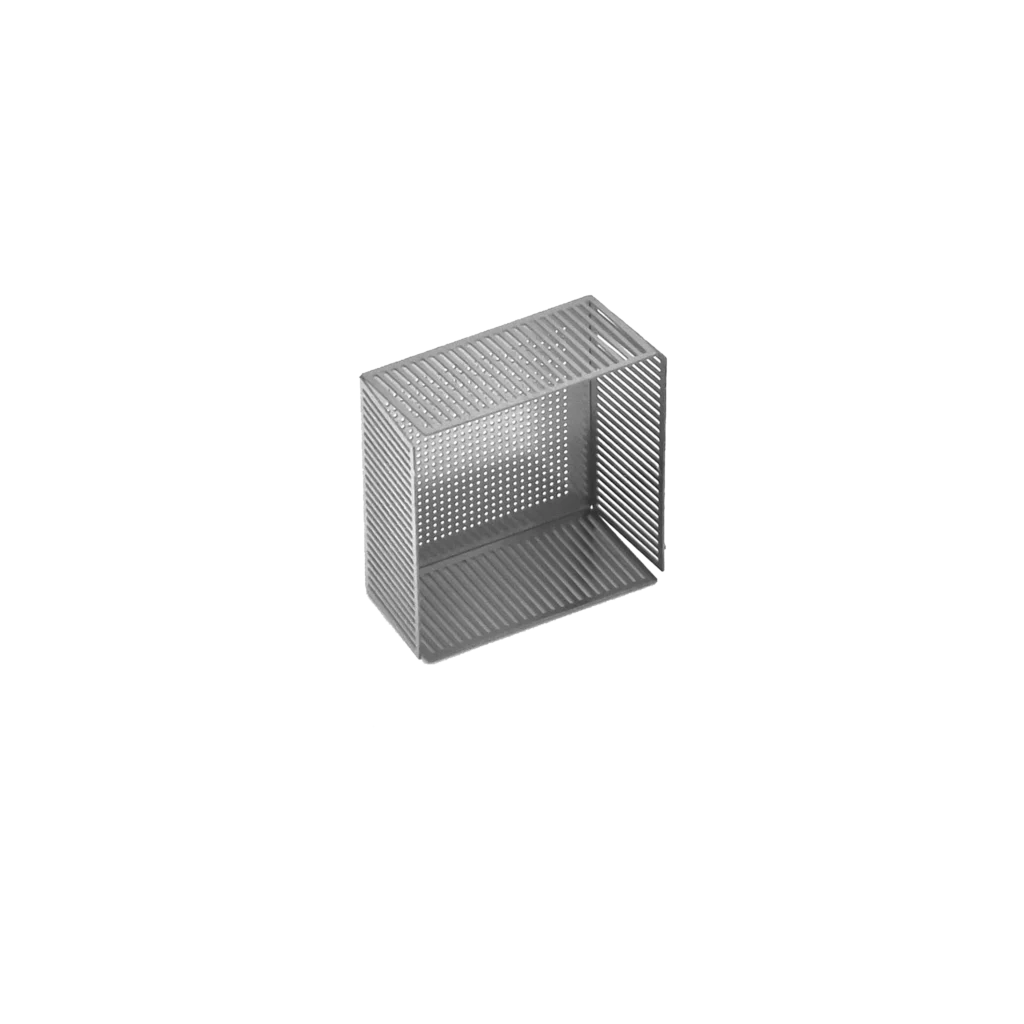

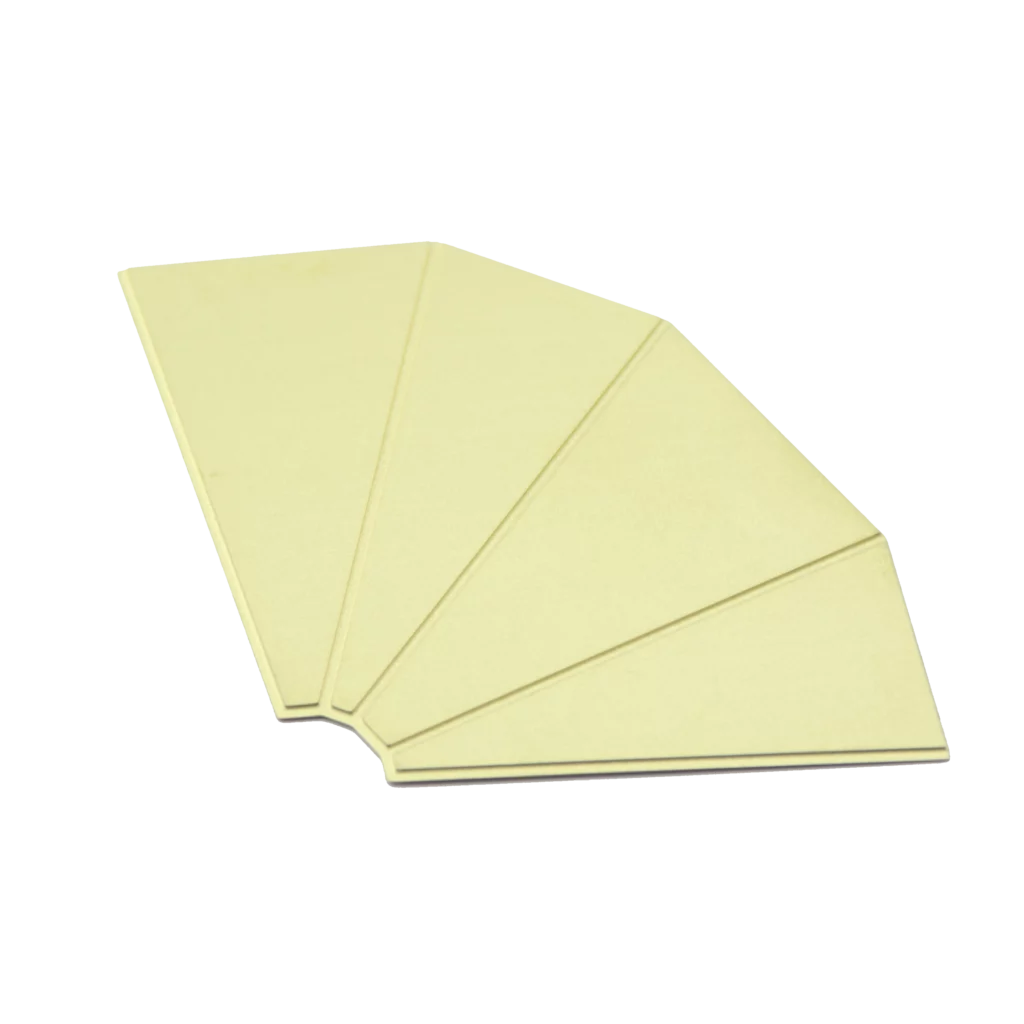

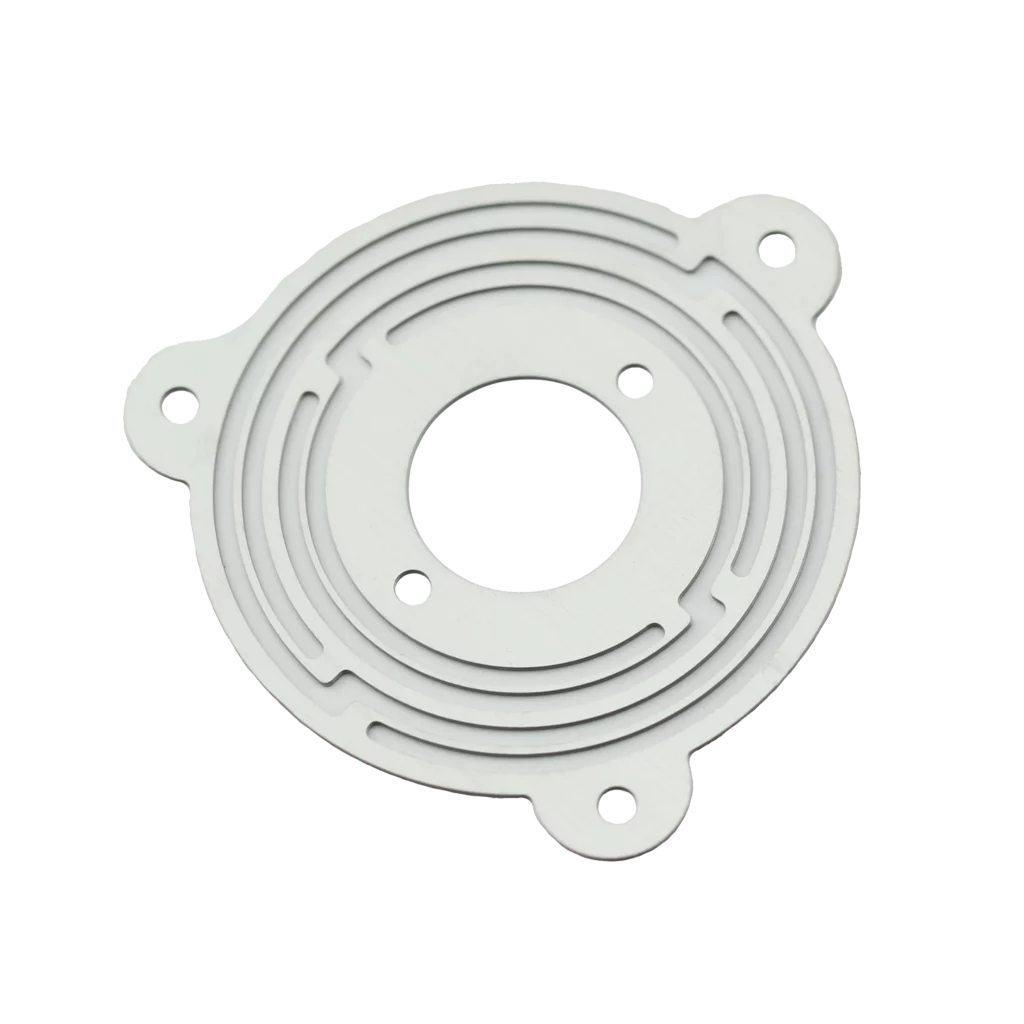

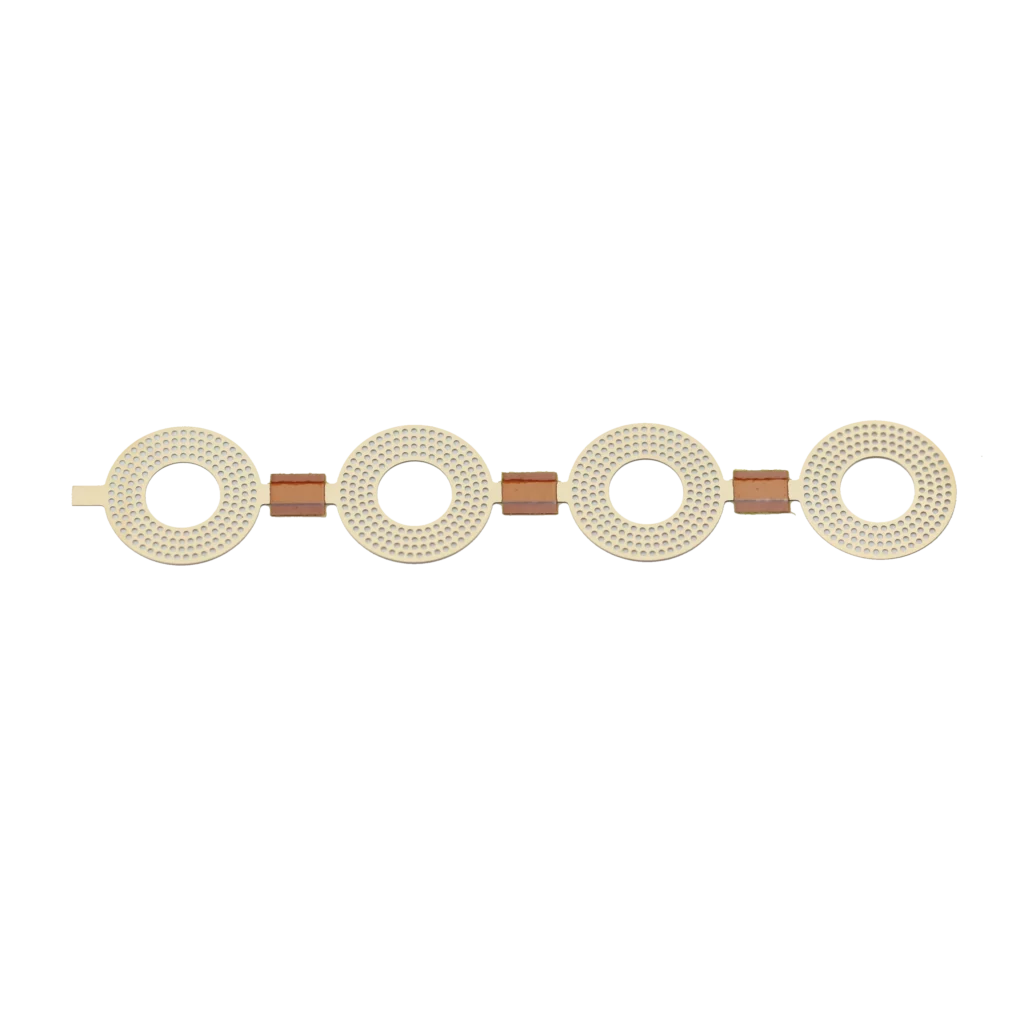

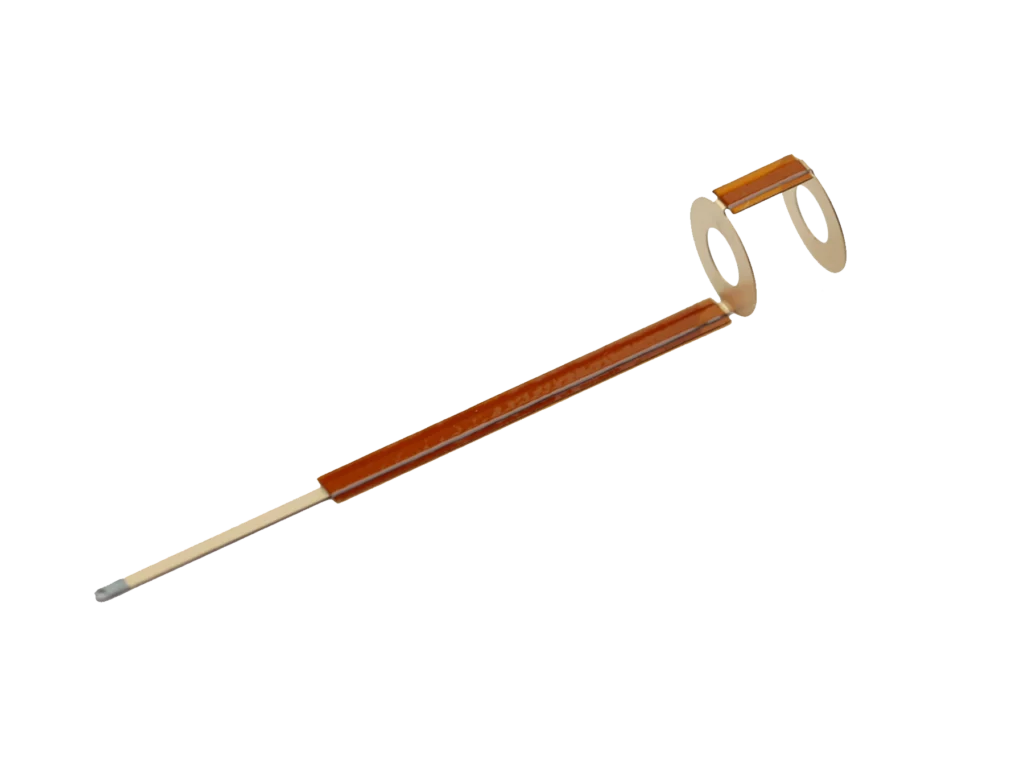

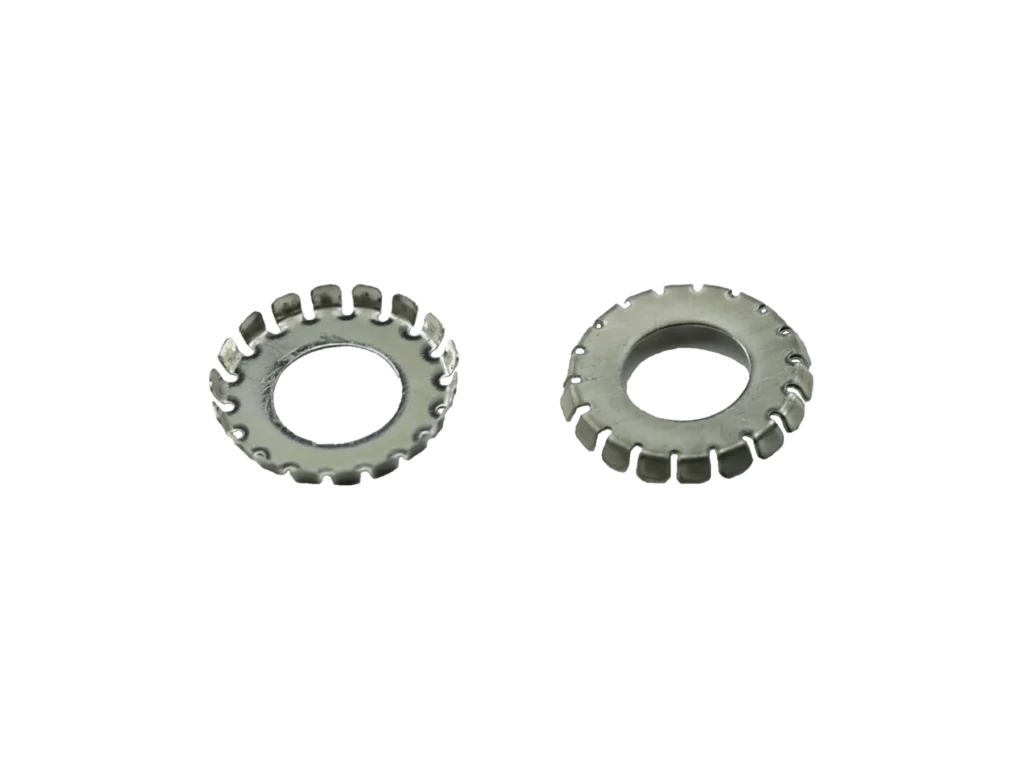

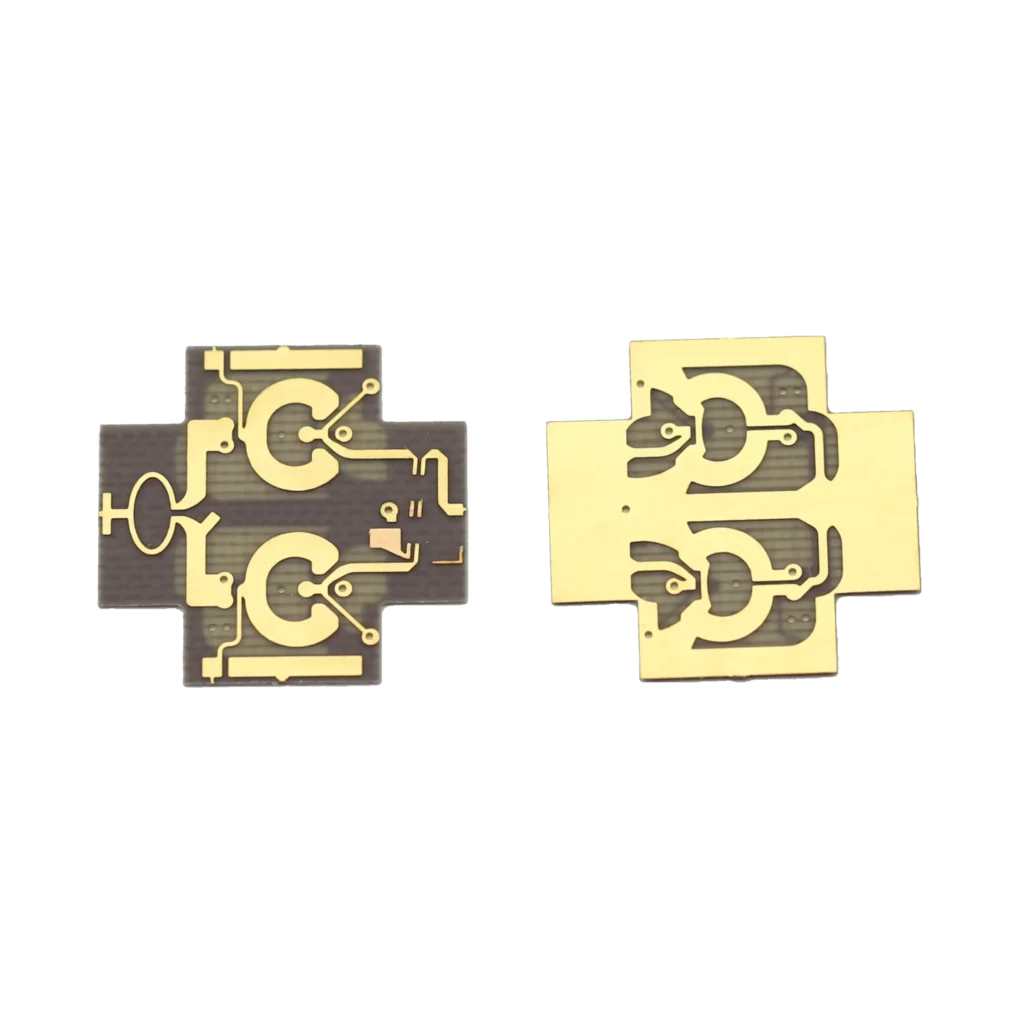

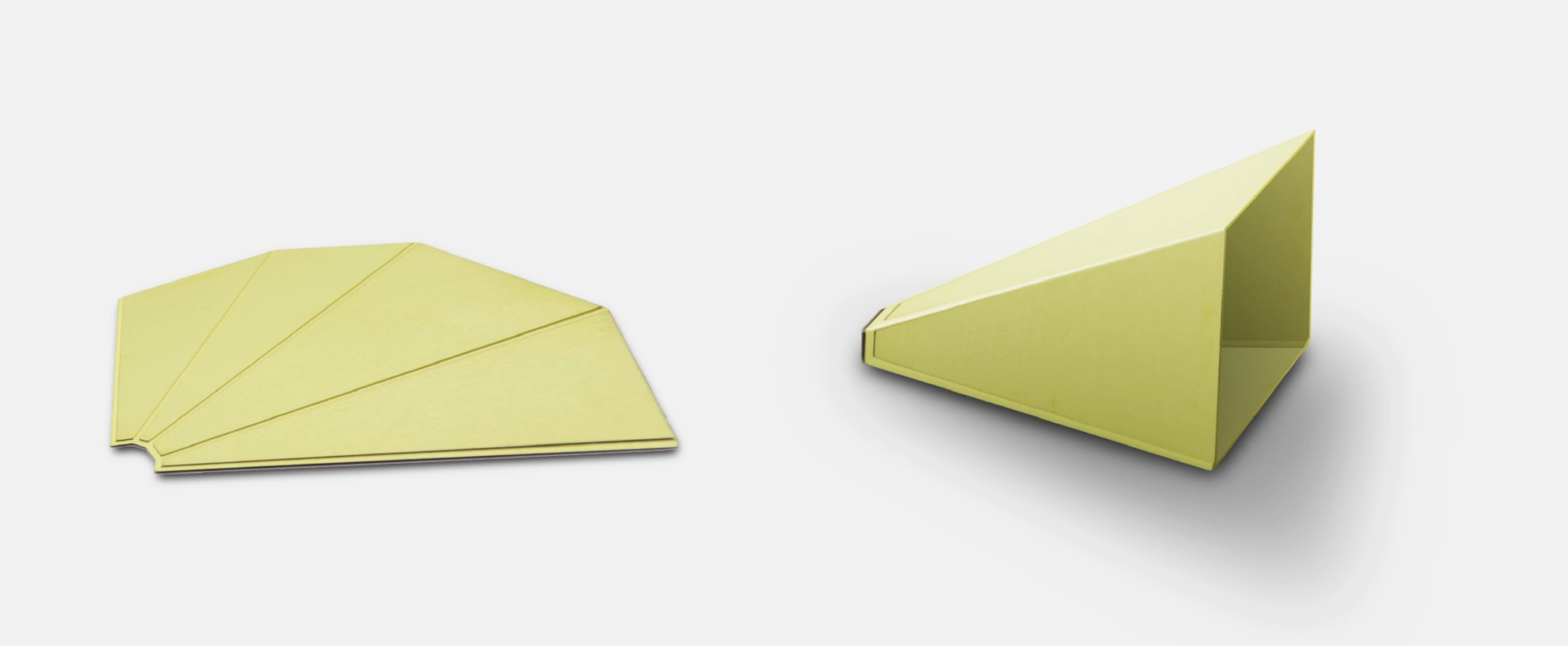

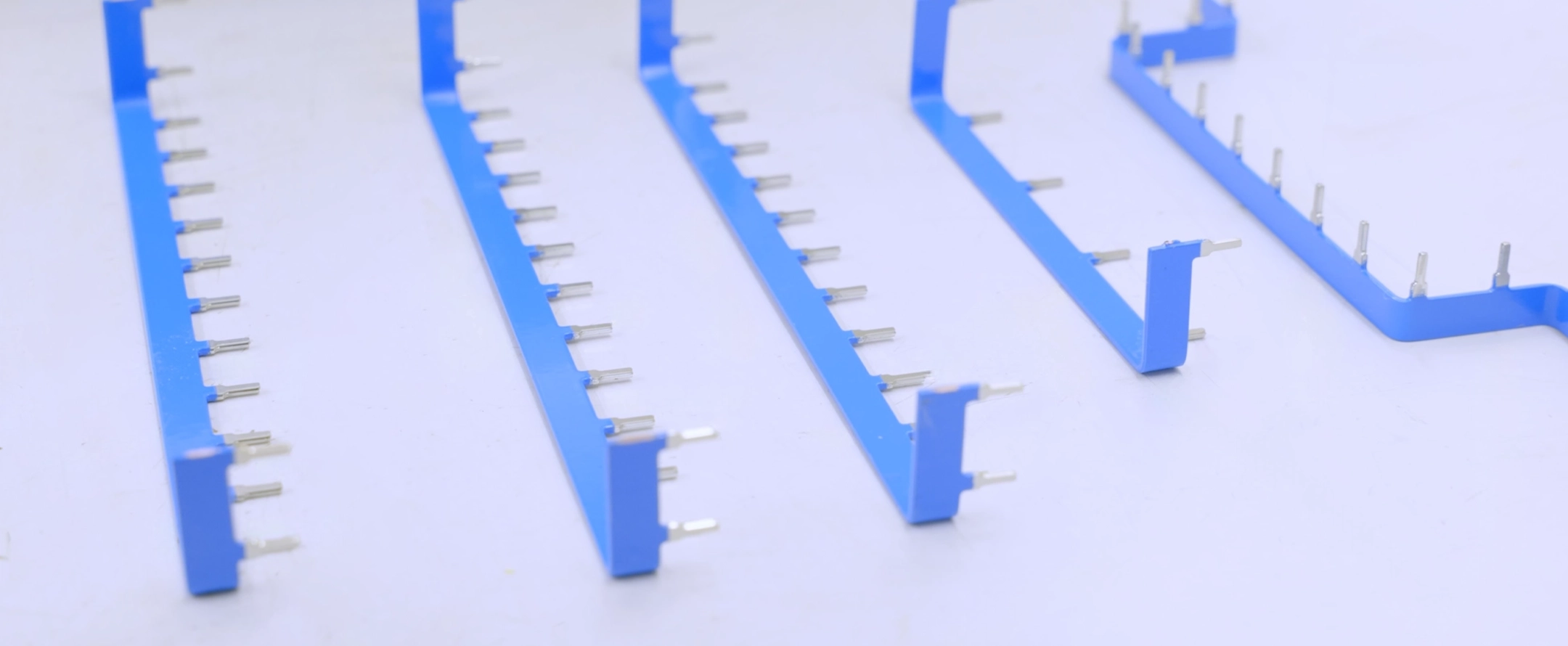

Our engineers, manufacturers, and quality assurance specialists turn ideas into precision parts through collaboration, engineering, and expert machining processes. We’re known for our specialties in photochemical etching, forming, bonding, high-frequency laminate processing, and delivering accurate parts with tight tolerances.

E-Fab engineers are well-versed in the benefits of various metals and materials and can offer expert guidance on what’s best for any part. We process Nickel Iron, Copper Nickel, Nickel Silver, Phosphor Bronze, Steel, Invar, Hy-Mu 80, and Inconel 600 in addition to the metals on the left. Let us know if you are interested in working with another material, and we can help source it. We welcome your questions and are ready to solve your biggest challenges.

E-Fab has operated under the guiding principles of innovation, expertise, and experimentation since our earliest days. Our commitment to service and problem-solving starts by listening to what problems our customers are trying to solve and the challenges they are facing. From there, our engineers and materials experts look for the best solutions, and our manufacturing specialists detail the process to deliver the best result. E-Fab continues to invest in our people and technology to layer in new capabilities and better serve our clients. We’ve acted like this since 1982 and continue to look forward to serving leading companies in multiple industries for decades to come.

We are an expert team of engineers, manufacturers, and quality assurance specialists that deliver precision parts with ultimate accuracy. We serve technology companies, defense contractors, medical equipment manufacturers, and innovators from our Santa Clara, California headquarters.

We’d love to hear about your challenges and answer your questions. Reach out, and let’s get it done.

1075 Richard Avenue

Santa Clara, CA 95050

United States

Main Phone: (408) 727-5218

Fax: (408) 988-3342

Email Us